Wire Wound Resistor Size

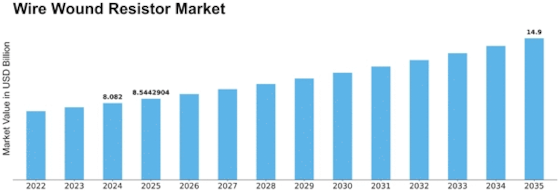

Wire wound Resistor Market Growth Projections and Opportunities

The Wirewound Resistor Market is significantly influenced by several market factors that collectively shape its dynamics. One key factor is the growing demand for electronic devices across various industries. As technology continues to advance, the need for precise and reliable resistors, such as wirewound resistors, has surged. These resistors are vital components in electronic circuits, ensuring stable and controlled electrical currents. The expanding consumer electronics market, driven by the constant evolution of smartphones, laptops, and other gadgets, has propelled the Wirewound Resistor Market forward.

Another critical market factor is the increasing emphasis on energy efficiency. Wirewound resistors play a pivotal role in enhancing the energy efficiency of electronic devices by controlling and managing power dissipation. With a rising global awareness of energy conservation and sustainable practices, industries are increasingly adopting components that contribute to more energy-efficient products. Wirewound resistors, known for their precision and ability to handle high power, align well with these energy-conscious trends, thereby driving their demand.

Moreover, the automotive industry is a significant contributor to the Wirewound Resistor Market's growth. The automotive sector is undergoing a rapid transformation with the integration of advanced electronics, including electric vehicles (EVs), smart infotainment systems, and autonomous driving technologies. Wirewound resistors find extensive applications in these electronic components, ensuring optimal performance and reliability. As the automotive industry continues its technological evolution, the demand for wirewound resistors is poised to grow in tandem.

Market factors are also shaped by the regulatory landscape, particularly concerning safety standards in various industries. Wirewound resistors are known for their ability to withstand high temperatures and provide stable performance in challenging environments. This characteristic makes them indispensable in applications where safety and reliability are paramount, such as aerospace and defense. Stringent regulations and standards in these sectors drive the adoption of high-quality components like wirewound resistors.

Global economic trends also influence the Wirewound Resistor Market. Economic growth, industrialization, and increased investments in infrastructure contribute to the expansion of the market. As more countries focus on developing their manufacturing capabilities and technological infrastructure, the demand for electronic components, including wirewound resistors, experiences a corresponding upswing.

Competitive factors also play a vital role in shaping the Wirewound Resistor Market. With numerous players in the market, innovation and cost-effectiveness become critical differentiators. Companies strive to develop resistors with improved performance characteristics, greater power-handling capabilities, and smaller form factors. Additionally, pricing strategies and the ability to offer customized solutions influence a company's competitiveness in the market.

Leave a Comment