Technological Advancements

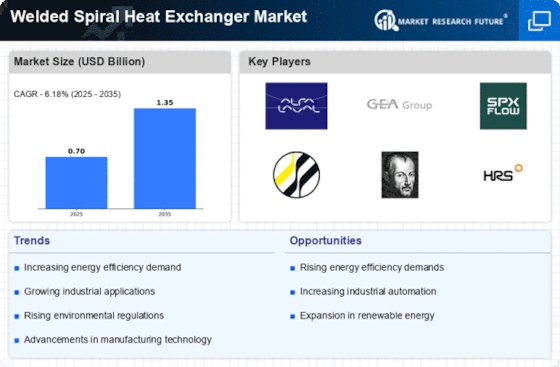

The Welded Spiral Heat Exchanger Market is benefiting from continuous technological advancements that enhance the performance and efficiency of heat exchangers. Innovations in materials, design, and manufacturing processes are leading to the development of more efficient welded spiral heat exchangers. These advancements not only improve thermal performance but also reduce maintenance costs and extend the lifespan of the equipment. As industries seek to optimize their operations, the demand for technologically advanced heat exchangers is expected to rise. Recent market data indicates that the introduction of new technologies could result in a 6% increase in the adoption rate of welded spiral heat exchangers, as companies prioritize efficiency and reliability in their thermal management systems.

Increasing Industrialization

The Welded Spiral Heat Exchanger Market is experiencing a notable surge due to the rapid pace of industrialization across various sectors. Industries such as chemical processing, oil and gas, and food and beverage are increasingly adopting advanced heat exchange technologies to enhance operational efficiency. The demand for energy-efficient solutions is driving the need for welded spiral heat exchangers, which are known for their compact design and high thermal performance. As industries expand, the requirement for effective heat transfer solutions becomes paramount, thereby propelling the growth of the Welded Spiral Heat Exchanger Market. According to recent data, the industrial sector's growth is projected to contribute significantly to the market, with an expected increase in demand for heat exchangers by approximately 5% annually over the next five years.

Growing Focus on Renewable Energy

The Welded Spiral Heat Exchanger Market is poised for growth as the focus on renewable energy sources intensifies. With the global shift towards sustainable energy solutions, industries are increasingly utilizing welded spiral heat exchangers in applications such as biomass energy, solar thermal systems, and geothermal energy. These heat exchangers are particularly effective in managing the thermal processes involved in renewable energy generation, thereby enhancing overall system efficiency. Market analysis suggests that the integration of welded spiral heat exchangers in renewable energy projects could lead to a 10% increase in market share within the next five years, as more companies seek to optimize their energy systems and reduce reliance on fossil fuels.

Rising Demand in HVAC Applications

The Welded Spiral Heat Exchanger Market is witnessing a surge in demand driven by the growing need for efficient heating, ventilation, and air conditioning (HVAC) systems. As urbanization continues to rise, the demand for effective HVAC solutions is becoming increasingly critical. Welded spiral heat exchangers are particularly well-suited for HVAC applications due to their compact design and high heat transfer efficiency. This trend is further supported by the increasing emphasis on energy-efficient building designs and retrofitting existing systems. Market projections indicate that the HVAC sector could account for a significant portion of the welded spiral heat exchanger market, with an anticipated growth rate of 8% over the next few years, as more buildings adopt advanced thermal management solutions.

Regulatory Compliance and Standards

The Welded Spiral Heat Exchanger Market is influenced by stringent regulatory frameworks aimed at improving energy efficiency and reducing emissions. Governments worldwide are implementing regulations that mandate the use of energy-efficient technologies in industrial processes. This regulatory environment encourages industries to invest in welded spiral heat exchangers, which offer superior performance and lower energy consumption compared to traditional heat exchangers. Compliance with these regulations not only helps companies avoid penalties but also enhances their reputation as environmentally responsible entities. The market data indicates that adherence to these standards is likely to drive a 7% increase in the adoption of welded spiral heat exchangers over the next few years, as industries seek to align with sustainability goals.