Top Industry Leaders in the Vertical Lift Module VLM Carousel-Based Automated Storage Retrieval Systems ASRS Market

The Competitive Landscape of the Vertical Lift Module VLM Carousel-Based Automated Storage Retrieval Systems ASRS Market

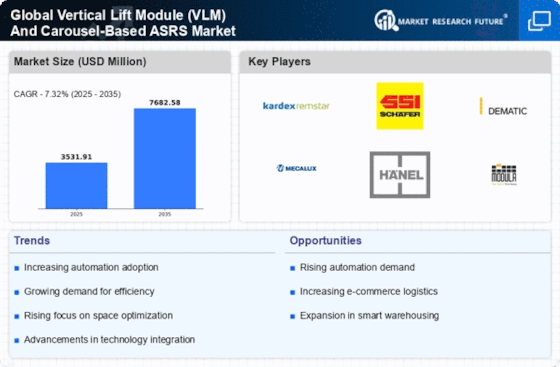

In the ever-evolving realm of warehouse automation, vertical lift modules (VLMs) and carousel-based automated storage and retrieval systems (ASRS) have ascended to center stage. These nimble storage heroes, scaling the heights of warehouses and spinning with precision, optimize space, streamline picking, and boost overall operational efficiency. To navigate this dynamic market, where every inch counts and every second matters, understanding the competitive landscape, adopted strategies, key players, and emerging trends is crucial for both established and aspiring participants.

Some of the Vertical Lift Module (VLM) and Carousel Based Automated Storage and Retrieval Systems (ASRS) companies listed below:

- SSI SCHAEFER

- Bastian Systems

- Vanderlande

- Hänel Storage Systems

- Mecalux S.A.

- THE BEUMER GROUP GMBH & CO. KG

- Daifuku Co. Ltd

- Kardex

- Autocrib

- Vidir Solutions, Inc.

Strategies Adopted by Leaders:

- Embracing Innovation and Cutting-Edge Technologies: Investing in R&D to integrate advancements like high-speed robotic grippers, automated bin replenishment systems, and enhanced software intelligence differentiates solutions and caters to the need for faster picking, improved accuracy, and real-time inventory management.

- Prioritizing Customer Support and Training: Providing comprehensive customer support, including installation, maintenance, and ongoing technical assistance, fosters trust and ensures optimal system performance.

- Partnerships and Ecosystem Building: Collaborating with warehouse automation specialists, software developers, logistics consultants, and material handling equipment manufacturers expands reach, offers complete solutions, and strengthens brand presence.

- Focus on Sustainability and Energy Efficiency: Utilizing energy-efficient components, minimizing waste in production processes, and offering compliant packaging cater to customers with growing environmental awareness.

- Cost-Effectiveness and Return on Investment: Offering competitive pricing, demonstrating clear ROI through increased productivity and reduced labor costs, and providing flexible financing options attract cost-conscious businesses.

Factors for Market Share Analysis:

- Product Portfolio and Technological Breadth: The range and sophistication of systems offered, encompassing diverse types of VLMs (single-mast, multi-mast, automated guided vehicle integrated) and carousels (horizontal, vertical, multi-tier), with varying storage capacities, picking speeds, software capabilities, and integration options, significantly impact market reach. Catering to specific applications, such as small parts storage, medical equipment management, or e-commerce fulfillment, requires tailored solutions and partnerships.

- Target Market Focus: Focusing on specific segments within the logistics ecosystem, such as manufacturing companies, e-commerce retailers, pharmaceutical distributors, or automotive parts suppliers, requires customized marketing strategies and technical specifications addressing their unique needs. Solidifying market share hinges on understanding these sector-specific concerns.

- Software and Integration Capabilities: Providing robust software platforms for inventory management, order fulfillment, and system control, coupled with seamless integration with existing warehouse management systems (WMS) and enterprise resource planning (ERP) software, enhances efficiency and data visibility.

- Space Optimization and Flexibility: Maximizing vertical space utilization, offering modular designs for easy expansion, and adapting to diverse warehouse layouts are crucial for optimizing footprint and adapting to changing needs.

- Ergonomics and User Interface: Ensuring user-friendly interfaces, minimizing worker fatigue through ergonomic design, and providing comprehensive training programs are essential for maximizing operator productivity and minimizing errors.

New and Emerging Companies:

- Niche-Focused Specialists: Companies like Knapp and Swisslog specialize in developing customized VLM and carousel solutions for specific industries like pharmaceutical labs, food and beverage distribution, or automotive parts management, offering unparalleled expertise and tailored configurations.

- Software-Centric Platforms: Companies like Geek+ and Locus Robotics focus on developing intelligent software platforms that can be integrated with existing ASRS systems, optimizing picking routes, managing inventory, and automating workflows.

- Open-Source Hardware Advocates: Companies like Open Automation and RepRap promote open-source VLM and carousel designs and readily available fabrication instructions, empowering researchers and DIY enthusiasts with customization options and fostering innovation within the community.

Latest Company Updates:

Oct. 31, 2023, Mobile robot developer Geek+ launched the world's tallest warehouse retrieval robot, RoboShuttle. The new mobile automated storage and retrieval system (ASRS) is designed to support warehouse automation up to 12m (40 ft). The new RoboShuttle solution has already been installed in North America and Asia and is being deployed for several major global retailers.

Oct. 31, 2023, Anderson Dahlen, a custom stainless steel and specialty alloy manufacturing company, announced that it had integrated Aptean ERP with an automated storage and retrieval system at its two facilities, with over 220,000 ft² of production and warehouse capacity.

Oct. 16, 2023, Greenspace Industrial, a warehouse automation and industrial solutions company, unveiled its latest advancement in automated storage and retrieval systems (ASRS) by introducing the Mini Load ASRS. Greenspace Industrial's innovative mini-load ASRS system enhances warehousing efficiency. This Mini Load ASRS is designed to tackle today's warehouses' most pressing challenges, from space limitations to labor costs and order accuracy.

June 14, 2023, Falcon Autotech, a leading global provider of intralogistics automation solutions, launched an automated storage and retrieval system (ASRS), NEO. NEO includes bots that can reach target bins across X, Y & Z dimensions. It leverages robotics, AI, and advanced sensors to automate goods' storage and retrieval processes. The ASRS enables the storing and retrieving goods in an overlaid grid within the warehouse without complex engineering.

May 18, 2023, OSARO, a global leader in machine-learning-enabled robotics for e-commerce, announced a partnership with Geek+ to integrate robotic warehouse solutions. The partnership will enable their customers to leverage integrated access to OSARO's advanced picking robots with Geek+ autonomous mobile robots and automated storage and retrieval systems.