US Spunbond Nonwoven Market Summary

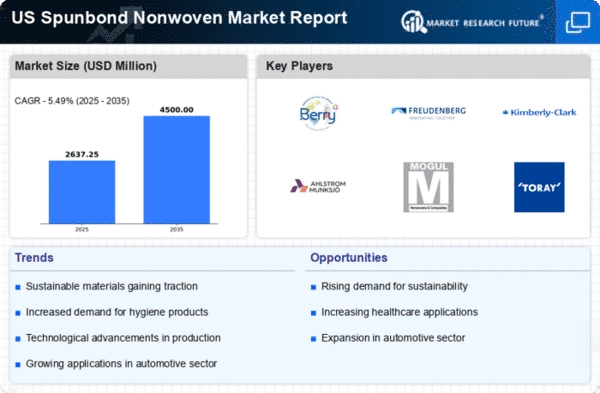

As per Market Research Future analysis, the US spunbond nonwoven market size was estimated at 2500.0 USD Million in 2024. The US spunbond nonwoven market is projected to grow from 2637.25 USD Million in 2025 to 4500.0 USD Million by 2035, exhibiting a compound annual growth rate (CAGR) of 5.4% during the forecast period 2025 - 2035

Key Market Trends & Highlights

The US spunbond nonwoven market is experiencing robust growth driven by sustainability and technological advancements.

- Sustainability initiatives are increasingly shaping product development in the spunbond nonwoven sector.

- Technological advancements are enhancing manufacturing processes, leading to improved product quality and efficiency.

- The healthcare segment remains the largest, while the automotive sector is identified as the fastest-growing application for spunbond nonwovens.

- Rising demand in the healthcare sector and an increased focus on hygiene products are key drivers propelling market expansion.

Market Size & Forecast

| 2024 Market Size | 2500.0 (USD Million) |

| 2035 Market Size | 4500.0 (USD Million) |

| CAGR (2025 - 2035) | 5.49% |

Major Players

Berry Global (US), Freudenberg Performance Materials (DE), Kimberly-Clark Corporation (US), Ahlstrom-Munksjö (FI), Mogul Nonwoven (TR), Toray Industries (JP), Fitesa (BR), Sandler AG (DE)