Expansion of Medical Applications

The medical sector is witnessing a notable expansion in the use of polyurethane elastomers, which serves as a key driver for the market. These materials are increasingly utilized in medical devices, prosthetics, and wound care products due to their biocompatibility and flexibility. In 2025, the medical applications segment is expected to account for around 10% of the total market share. The ongoing advancements in healthcare technology and the rising demand for innovative medical solutions are likely to propel the growth of polyurethane elastomers in this sector. As healthcare providers seek reliable and effective materials, the polyurethane elastomers market is positioned to benefit from this upward trend.

Growth in Construction Activities

The construction industry plays a pivotal role in driving the polyurethane elastomers market. With the increasing investment in infrastructure development across the United States, the demand for high-performance materials is on the rise. Polyurethane elastomers are favored for their durability, flexibility, and resistance to environmental factors, making them ideal for applications in roofing, flooring, and insulation. In 2025, the construction sector is anticipated to contribute around 25% to the overall market. This growth is further supported by the trend towards sustainable building practices, where polyurethane elastomers are utilized for their energy-efficient properties, thereby enhancing the market's potential.

Increased Focus on Consumer Goods

The consumer goods sector is emerging as a vital driver for the polyurethane elastomers market. With a growing preference for high-quality, durable products, manufacturers are increasingly incorporating polyurethane elastomers into various applications, including footwear, sporting goods, and household items. The market for consumer goods is projected to grow by approximately 20% in 2025, driven by the demand for lightweight and resilient materials. This trend is further supported by consumer awareness regarding product longevity and performance, which positions polyurethane elastomers as a favorable choice. Consequently, the polyurethane elastomers market is likely to expand as it aligns with consumer expectations.

Rising Demand in Automotive Sector

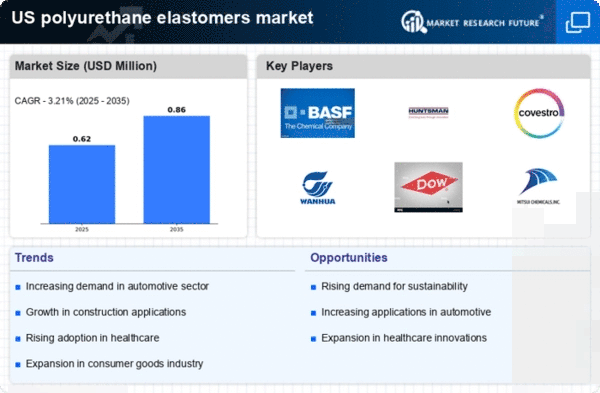

The automotive sector is a significant driver for the polyurethane elastomers market. As manufacturers increasingly seek lightweight and durable materials, the demand for polyurethane elastomers is projected to rise. In 2025, the automotive industry is expected to account for approximately 30% of the total market share. This growth is attributed to the material's excellent mechanical properties, which enhance fuel efficiency and reduce emissions. Furthermore, the shift towards electric vehicles is likely to bolster the demand for advanced materials, including polyurethane elastomers, due to their versatility and performance characteristics. As a result, the polyurethane elastomers market is poised to benefit from the automotive sector's ongoing transformation.

Technological Innovations in Manufacturing

Technological advancements in the manufacturing processes of polyurethane elastomers are significantly influencing the market. Innovations such as improved polymerization techniques and the development of new formulations are enhancing the performance characteristics of these materials. In 2025, it is estimated that advancements in manufacturing technology could lead to a 15% increase in production efficiency. This not only reduces costs but also allows for the creation of specialized products tailored to specific applications. As manufacturers continue to invest in research and development, the polyurethane elastomers market is likely to experience a surge in product offerings, catering to diverse industrial needs.