Growth in Automotive Electronics

The plastic film-capacitors market is poised for growth due to the increasing integration of electronic components in the automotive sector. As vehicles become more technologically advanced, the demand for reliable capacitors to support various electronic systems, such as infotainment, safety, and power management, escalates. The automotive electronics market in the US is projected to exceed $100 billion by 2025, indicating a substantial opportunity for plastic film capacitors. These components are essential for ensuring the stability and efficiency of automotive electronics, which may lead to a heightened demand for plastic film-capacitors in the automotive industry. This trend underscores the potential for growth within the plastic film-capacitors market as it aligns with the automotive industry's technological advancements.

Expansion of Consumer Electronics

The plastic film-capacitors market is significantly influenced by the expansion of the consumer electronics sector in the US. With the proliferation of smart devices, including smartphones, tablets, and wearables, the demand for compact and efficient capacitors is on the rise. Plastic film capacitors are favored for their reliability and performance in high-frequency applications, making them ideal for modern electronics. The consumer electronics market is expected to reach a valuation of over $400 billion by 2026, which will likely drive the plastic film-capacitors market as manufacturers seek to enhance device performance. This trend suggests a promising outlook for the plastic film-capacitors market, as it adapts to the evolving needs of the electronics industry.

Increased Focus on Energy Efficiency

The plastic film-capacitors market benefits from the heightened focus on energy efficiency across various industries in the US. As businesses and consumers alike seek to reduce energy consumption and lower operational costs, the demand for energy-efficient components rises. Plastic film capacitors are recognized for their low energy losses and high performance, making them a preferred choice in energy-saving applications. The US government has also introduced regulations aimed at promoting energy efficiency, which could further stimulate the plastic film-capacitors market. This emphasis on energy efficiency suggests a favorable environment for the growth of plastic film capacitors, as industries strive to meet regulatory standards and consumer expectations.

Rising Demand in Renewable Energy Sector

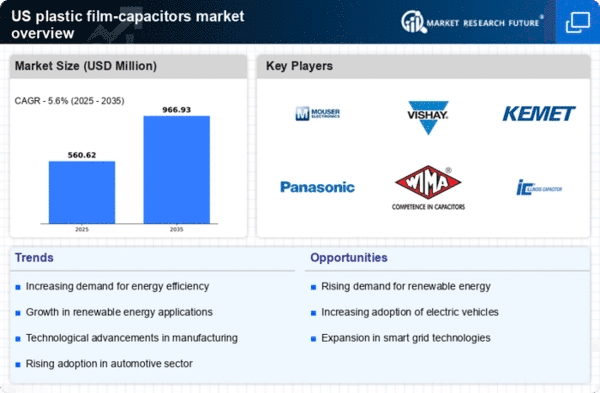

The plastic film-capacitors market is witnessing a significant increase in demand due to the growing adoption of renewable energy sources in the US. As solar and wind energy installations proliferate, the need for efficient energy storage solutions becomes paramount. Plastic film capacitors are integral in managing power fluctuations and enhancing the efficiency of renewable energy systems. The market is projected to grow at a CAGR of approximately 8% over the next five years, driven by this trend. Furthermore, the US government has implemented various incentives to promote renewable energy, further bolstering the demand for plastic film capacitors in energy applications. This growth trajectory indicates a robust future for the plastic film-capacitors market, as it aligns with national energy goals and sustainability efforts.

Technological Innovations in Capacitor Design

The plastic film-capacitors market is expected to experience growth driven by ongoing technological innovations in capacitor design. Advances in materials science and manufacturing processes have led to the development of more efficient and compact capacitors, which are essential for modern applications. Innovations such as improved dielectric materials and enhanced manufacturing techniques are enabling the production of plastic film capacitors with superior performance characteristics. This trend is particularly relevant in sectors such as telecommunications and industrial automation, where high-performance capacitors are critical. As these technological advancements continue to evolve, they may significantly impact the plastic film-capacitors market, fostering a competitive landscape that encourages further innovation and development.