Increased Production Efficiency

Advancements in manufacturing processes are significantly enhancing production efficiency within the molded fiber-egg-carton market. Innovations such as automated molding techniques and improved drying processes are enabling manufacturers to produce higher volumes of egg cartons with reduced energy consumption. This efficiency not only lowers production costs but also enhances the overall quality of the products. As a result, the molded fiber-egg-carton market is witnessing a surge in output, which is essential for meeting the rising demand from the food industry. Reports indicate that production efficiency improvements could lead to a reduction in costs by up to 20%, thereby making molded fiber products more competitive against traditional packaging materials.

Consumer Awareness and Education

Consumer awareness regarding the environmental impact of packaging materials is a driving force in the molded fiber-egg-carton market. Educational campaigns and information dissemination about the benefits of sustainable packaging are fostering a more informed consumer base. As individuals become more knowledgeable about the ecological footprint of their purchases, they are more likely to choose products that utilize molded fiber packaging. This shift in consumer behavior is reflected in market trends, with a reported 30% increase in preference for sustainable packaging options over the past year. Consequently, the molded fiber-egg-carton market is likely to see continued growth as consumers increasingly demand products that align with their values.

Rising Demand for Eco-Friendly Packaging

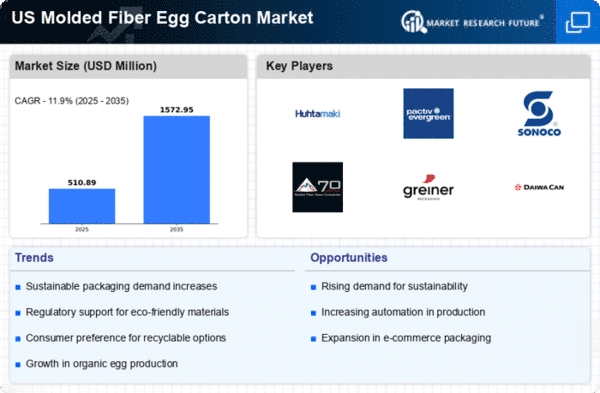

The molded fiber-egg-carton market experiences a notable increase in demand driven by the growing consumer preference for eco-friendly packaging solutions. As environmental awareness escalates, consumers are gravitating towards sustainable products, which has led to a shift in purchasing behavior. In the US, the market for sustainable packaging is projected to reach approximately $400 billion by 2027, with molded fiber products playing a crucial role. This trend is further supported by regulatory measures aimed at reducing plastic waste, compelling manufacturers to adopt biodegradable alternatives. Consequently, the molded fiber-egg-carton market is positioned to benefit from this heightened focus on sustainability, as businesses seek to align their offerings with consumer values and environmental standards.

Regulatory Support for Sustainable Practices

The molded fiber-egg-carton market benefits from increasing regulatory support aimed at promoting sustainable practices within the packaging industry. Various state and federal initiatives are being implemented to encourage the use of biodegradable materials and reduce reliance on single-use plastics. For instance, legislation mandating the reduction of plastic waste is gaining traction, which is likely to bolster the demand for molded fiber products. This regulatory environment not only incentivizes manufacturers to innovate but also aligns with consumer expectations for environmentally responsible packaging. As a result, the molded fiber-egg-carton market is well-positioned to thrive in this supportive landscape, potentially leading to increased market share and growth opportunities.

Growth of Organic and Free-Range Egg Segments

The molded fiber-egg-carton market is positively influenced by the expansion of organic and free-range egg segments in the US. As consumers increasingly prioritize health and sustainability, the demand for organic eggs has surged, leading to a corresponding rise in the need for suitable packaging solutions. The organic egg market is expected to grow at a CAGR of 10% over the next five years, which directly impacts the molded fiber-egg-carton market. This growth is indicative of a broader trend towards natural and ethically produced food products, prompting egg producers to seek packaging that reflects their commitment to quality and sustainability. Thus, the molded fiber-egg-carton market stands to gain from this evolving consumer landscape.