Labor Shortages in Construction

The lightweight precast-wall-panel market is being positively impacted by the ongoing labor shortages in the construction industry. As skilled labor becomes increasingly scarce, construction companies are turning to prefabricated solutions that require less on-site labor. Lightweight precast wall panels can be manufactured off-site and quickly assembled, reducing the need for extensive labor during construction. This shift not only addresses labor shortages but also accelerates project timelines, making it an attractive option for developers. According to industry reports, the use of prefabricated materials can reduce construction time by up to 50%, thereby enhancing the appeal of lightweight precast-wall panels in the current market landscape.

Increased Focus on Safety Standards

the lightweight precast-wall-panel market benefits from the heightened focus on safety standards within the construction sector. As regulations become more stringent, builders are compelled to adopt materials that meet or exceed safety requirements. Lightweight precast wall panels are recognized for their structural integrity and fire resistance, making them a preferred choice for many construction projects. The National Fire Protection Association has established guidelines that encourage the use of non-combustible materials in building design. Consequently, the lightweight precast-wall-panel market is likely to see growth as more construction firms prioritize safety and compliance with evolving regulations.

Rising Demand for Energy Efficiency

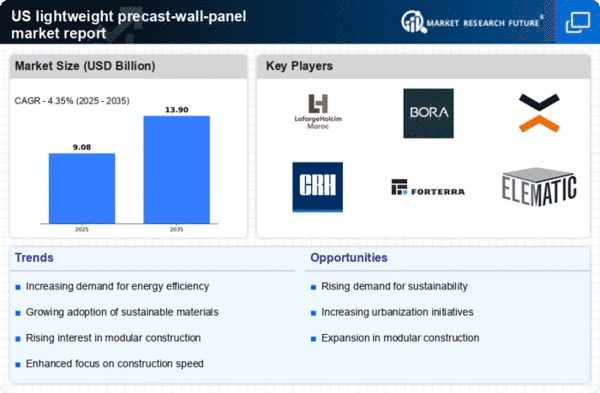

The lightweight precast-wall-panel market is experiencing a notable increase in demand driven by the growing emphasis on energy efficiency in construction. As energy costs continue to rise, builders and developers are seeking materials that enhance thermal performance and reduce energy consumption. Lightweight precast wall panels offer superior insulation properties, which can lead to energy savings of up to 30%. This trend aligns with the broader construction industry's shift towards sustainable practices, as energy-efficient buildings not only lower operational costs but also contribute to reduced carbon footprints. Consequently, The lightweight precast-wall-panel market is likely to benefit from this heightened focus on energy efficiency. More stakeholders are prioritizing materials that support green building certifications and standards.

Technological Innovations in Manufacturing

Technological advancements in manufacturing processes are playing a crucial role in shaping the lightweight precast-wall-panel market. Innovations such as automated production lines and advanced materials science are enhancing the efficiency and quality of precast wall panels. These technologies enable manufacturers to produce panels that are not only lighter but also stronger and more durable. The integration of Building Information Modeling (BIM) in design and construction processes further streamlines the workflow, allowing for better project management and reduced waste. As these technological innovations continue to evolve, they are likely to drive the lightweight precast-wall-panel market forward, offering competitive advantages to manufacturers who adopt these cutting-edge practices.

Government Incentives for Sustainable Construction

Government initiatives aimed at promoting sustainable construction practices are significantly influencing the lightweight precast-wall-panel market. Various federal and state programs offer financial incentives, such as tax credits and grants, to encourage the use of eco-friendly building materials. These incentives are designed to stimulate the adoption of innovative construction techniques that minimize environmental impact. For instance, the U.S. Department of Energy has launched programs that support the integration of energy-efficient materials in new construction projects. As a result, the lightweight precast-wall-panel market is likely to see increased adoption as builders take advantage of these financial benefits, thereby enhancing the market's growth potential.