Health and Safety Regulations

The food tray-sealing-machines market is also shaped by stringent health and safety regulations imposed by government agencies. These regulations mandate that food products must be packaged in a manner that ensures safety and minimizes contamination risks. As a result, food manufacturers are increasingly adopting advanced sealing technologies to comply with these standards. The market for food packaging machinery, including tray-sealing machines, is projected to grow at a rate of 4% annually, driven by the need for compliance with health regulations. This regulatory environment compels manufacturers to invest in high-quality sealing solutions, thereby propelling growth in the food tray-sealing-machines market.

Innovation in Packaging Materials

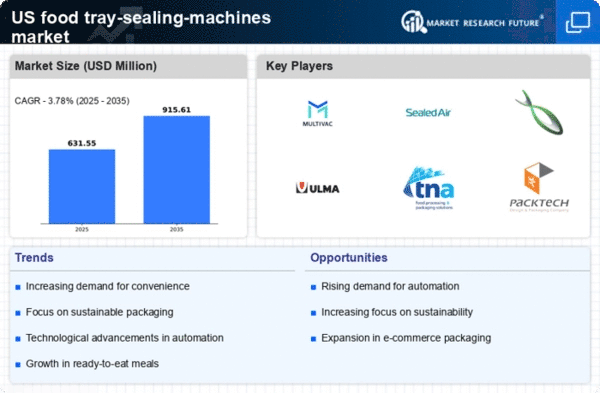

Innovation in packaging materials is a key driver for the food tray-sealing-machines market. The introduction of biodegradable and recyclable materials is gaining traction as consumers become more environmentally conscious. This shift is prompting food manufacturers to seek advanced sealing solutions that can accommodate these new materials while maintaining product integrity. The market for sustainable packaging is expected to grow by 7% annually, indicating a strong demand for food tray-sealing machines that can effectively seal eco-friendly materials. As manufacturers adapt to these changes, the food tray-sealing-machines market is likely to see increased investment in technology that supports sustainable practices.

Growth of E-commerce in Food Sector

The food tray-sealing-machines market is significantly influenced by the rapid growth of e-commerce within the food sector. As online grocery shopping becomes increasingly popular, food producers are adapting their packaging solutions to cater to this trend. The e-commerce food market in the US is expected to reach approximately $100 billion by 2026, indicating a robust demand for efficient packaging solutions. Food tray-sealing machines play a crucial role in ensuring that products remain fresh during transit, thereby enhancing customer satisfaction. This shift towards online food sales is likely to drive innovation and investment in the food tray-sealing-machines market, as companies strive to optimize their packaging processes for e-commerce.

Rising Demand for Convenience Foods

The food tray-sealing-machines market experiences a notable surge in demand due to the increasing consumer preference for convenience foods. As lifestyles become busier, consumers are gravitating towards ready-to-eat meals and packaged food products. This trend is reflected in the food service industry, where the market for convenience foods is projected to grow at a CAGR of approximately 5.5% over the next few years. Consequently, food manufacturers are investing in advanced sealing technologies to enhance product shelf life and maintain quality. The food tray-sealing-machines market is thus positioned to benefit from this shift, as manufacturers seek efficient solutions to meet consumer expectations for convenience and quality.

Expansion of Food Processing Industry

The food tray-sealing-machines market is positively impacted by the ongoing expansion of the food processing industry. As the demand for processed foods rises, manufacturers are increasingly investing in efficient packaging solutions to enhance production capabilities. The food processing sector in the US is projected to grow at a CAGR of 3.5%, driven by consumer preferences for convenience and quality. This growth necessitates the adoption of advanced sealing technologies to ensure product freshness and safety. Consequently, the food tray-sealing-machines market is expected to benefit from this expansion, as companies seek to optimize their packaging processes to meet the evolving demands of consumers.