Enhanced Data Analytics Capabilities

The digital inspection market is benefiting from enhanced data analytics capabilities that allow for more informed decision-making. Advanced analytics tools enable organizations to process and analyze inspection data more effectively, leading to improved operational efficiency and risk management. By leveraging big data and machine learning, companies can identify patterns and anomalies that may not be visible through traditional inspection methods. This capability is particularly valuable in sectors such as manufacturing and energy, where predictive maintenance can significantly reduce downtime and costs. As the demand for data-driven insights continues to grow, the digital inspection market is likely to expand, offering innovative solutions that enhance the overall inspection process.

Growing Demand for Quality Assurance

In the digital inspection market, the growing demand for quality assurance is a pivotal driver. Industries such as aerospace, automotive, and pharmaceuticals are increasingly prioritizing quality control to meet stringent regulatory requirements. This focus on quality assurance is leading to a higher adoption of digital inspection technologies, which offer enhanced precision and reliability. According to recent data, the market for quality assurance solutions is expected to reach $5 billion by 2026, reflecting a robust growth trajectory. As organizations strive to minimize defects and ensure compliance, the digital inspection market is likely to benefit from this heightened emphasis on quality, resulting in increased investments in inspection technologies and services.

Increased Investment in Infrastructure

The digital inspection market is poised for growth due to increased investment in infrastructure across the United States. Government initiatives aimed at modernizing transportation, utilities, and public facilities are driving the need for comprehensive inspection solutions. For example, the recent allocation of $1 trillion for infrastructure development is expected to create substantial demand for digital inspection services. These investments necessitate rigorous inspection processes to ensure safety and compliance with regulations. Consequently, the digital inspection market is likely to see a surge in demand as stakeholders seek efficient and reliable inspection methods to support these large-scale projects. This trend underscores the critical role of digital inspection technologies in facilitating infrastructure development.

Rising Focus on Environmental Sustainability

The digital inspection market is increasingly influenced by a rising focus on environmental sustainability. Companies are adopting digital inspection technologies to minimize waste and enhance resource efficiency. For instance, non-destructive testing methods are gaining traction as they reduce the need for material replacement and lower environmental impact. This shift towards sustainable practices is not only beneficial for the environment but also aligns with corporate social responsibility goals. As organizations strive to meet sustainability targets, the digital inspection market is likely to experience growth, driven by the demand for eco-friendly inspection solutions. This trend indicates a broader movement towards integrating sustainability into operational practices across various industries.

Technological Advancements in Inspection Tools

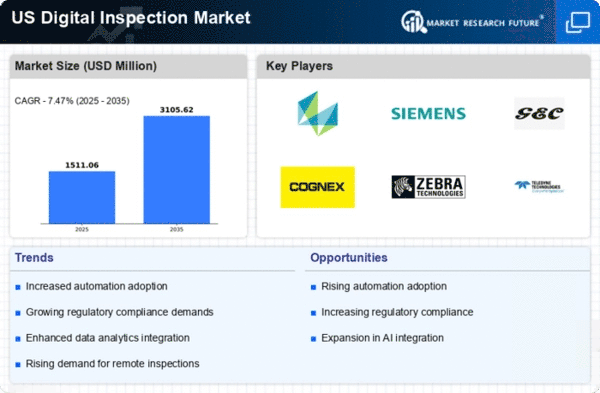

The digital inspection market is experiencing a surge due to rapid technological advancements in inspection tools. Innovations such as high-resolution imaging, drones, and IoT devices are enhancing the efficiency and accuracy of inspections. For instance, the integration of advanced sensors allows for real-time data collection, which is crucial for industries like construction and manufacturing. The market is projected to grow at a CAGR of approximately 10% from 2025 to 2030, driven by these technological improvements. As companies increasingly adopt these tools, the digital inspection market is likely to expand, providing significant opportunities for vendors and service providers. This trend indicates a shift towards more automated and precise inspection processes, which could redefine industry standards and practices.