Expansion of the Manufacturing Sector

The cnc polishing-machines market is benefiting from the expansion of the manufacturing sector in the United States. With a resurgence in domestic production, particularly in industries such as consumer goods and machinery, there is an increasing need for high-quality finishing processes. Recent statistics indicate that manufacturing output has risen by approximately 5% in the last year, creating a favorable environment for the adoption of advanced polishing technologies. As manufacturers seek to enhance their product offerings and meet consumer expectations, the demand for cnc polishing machines is likely to grow. This expansion not only drives sales but also encourages innovation within the cnc polishing-machines market, as companies invest in new technologies to improve efficiency and quality.

Increased Focus on Product Aesthetics

The cnc polishing-machines market is witnessing a heightened focus on product aesthetics, which is becoming a key differentiator in competitive industries. As consumers increasingly prioritize the visual appeal of products, manufacturers are compelled to invest in high-quality finishing processes. This trend is particularly evident in sectors such as luxury goods, electronics, and automotive, where the finish quality can significantly influence purchasing decisions. Market analysis suggests that the demand for aesthetically pleasing products is driving a growth rate of around 7% in the cnc polishing-machines market. Consequently, manufacturers are turning to advanced polishing technologies to achieve superior finishes, thereby enhancing their market position and meeting consumer expectations.

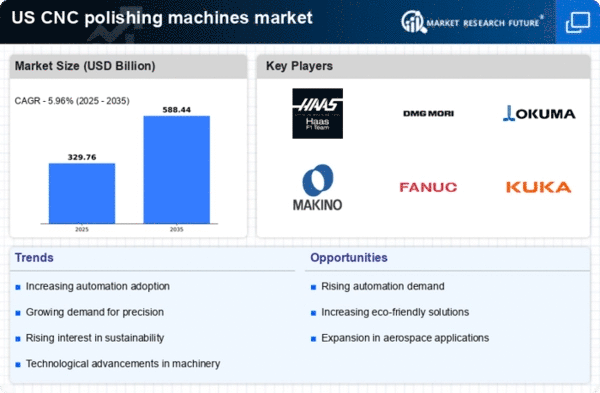

Rising Demand for Precision Engineering

The cnc polishing-machines market is experiencing a notable surge in demand driven by the increasing need for precision engineering across various sectors. Industries such as aerospace, automotive, and electronics are emphasizing high-quality finishes and tolerances, which are critical for performance and safety. This trend is reflected in the market data, indicating a projected growth rate of approximately 8% annually through 2027. As manufacturers strive to meet stringent quality standards, the adoption of advanced cnc polishing machines becomes essential. These machines not only enhance product quality but also improve operational efficiency, thereby reducing waste and production costs. Consequently, the rising demand for precision engineering is a significant driver for the CNC polishing machines market, pushing manufacturers to invest in state-of-the-art technology.

Growth in Automation and Smart Manufacturing

The cnc polishing-machines market is significantly influenced by the ongoing shift towards automation and smart manufacturing practices. As industries seek to enhance productivity and reduce labor costs, the integration of automated polishing solutions is becoming increasingly prevalent. According to recent data, the automation sector is expected to grow by over 10% annually, which directly impacts the demand for advanced cnc polishing machines. These machines are equipped with intelligent features such as real-time monitoring and adaptive control systems, allowing for greater precision and efficiency. This trend not only streamlines production processes but also minimizes human error, thereby improving overall product quality. The growth in automation is thus a crucial driver for the cnc polishing-machines market, as manufacturers aim to remain competitive in a rapidly evolving landscape.

Technological Innovations in Polishing Techniques

The cnc polishing-machines market is propelled by continuous technological innovations that enhance polishing techniques. Advancements in materials and machine capabilities are enabling manufacturers to achieve unprecedented levels of precision and efficiency. For instance, the introduction of new abrasives and polishing compounds has improved the effectiveness of polishing processes, leading to better surface finishes. Furthermore, the integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies is streamlining the design and production workflow, resulting in faster turnaround times. This innovation is reflected in the market, which is projected to grow at a rate of 6% annually as manufacturers seek to leverage these advancements. Thus, technological innovations are a vital driver for the cnc polishing-machines market, fostering a competitive edge for those who adopt them.