Innovation in Product Formulation

The airless bottle market is witnessing a surge in innovation related to product formulations. Brands are increasingly developing advanced formulations that require specialized packaging to maintain efficacy and stability. Airless bottles are particularly suited for these formulations, as they prevent contamination and oxidation, ensuring that products remain effective throughout their shelf life. The market for high-performance skincare products is expected to grow by 15% annually, which could drive demand for airless packaging solutions. This innovation in product formulation aligns with the airless bottle market's growth, as brands seek to differentiate themselves through superior product quality and packaging.

Growing E-Commerce and Online Retail

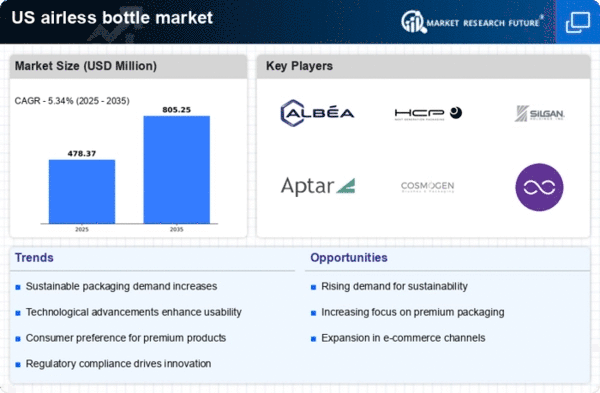

The airless bottle market is being positively influenced by the growth of e-commerce and online retail channels. As more consumers turn to online shopping for beauty and personal care products, the demand for packaging that ensures product integrity during shipping is increasing. Airless bottles, with their ability to protect contents from external factors, are becoming a preferred choice for brands selling online. In 2025, e-commerce sales in the beauty sector are expected to account for over 30% of total sales, highlighting the importance of effective packaging solutions. This trend presents a significant opportunity for the airless bottle market to expand its reach and cater to the needs of online retailers.

Rising Demand for Eco-Friendly Packaging

The airless bottle market is experiencing a notable shift towards eco-friendly packaging solutions. As consumers become increasingly aware of environmental issues, there is a growing demand for products that minimize waste and utilize sustainable materials. This trend is reflected in the market, where eco-conscious brands are adopting airless bottles to enhance their product offerings. In 2025, the market for sustainable packaging in the beauty and personal care sector is projected to reach approximately $30 billion, indicating a robust growth trajectory. The airless bottle market is well-positioned to capitalize on this trend, as these bottles not only reduce product waste but also extend shelf life, thereby appealing to environmentally aware consumers.

Regulatory Compliance and Safety Standards

The airless bottle market is increasingly influenced by regulatory compliance and safety standards. As consumer safety becomes a priority, brands are required to adhere to stringent regulations regarding packaging materials and product safety. Airless bottles, which often utilize materials that meet these safety standards, are gaining traction among manufacturers. The US market is expected to see a rise in regulations aimed at ensuring product safety, which could drive demand for compliant packaging solutions. In 2025, the market for compliant packaging is projected to grow by 10%, indicating a clear opportunity for the airless bottle market to align with these regulatory trends and enhance its market position.

Increased Investment in Research and Development

Investment in research and development (R&D) within the airless bottle market is on the rise. Companies are allocating significant resources to develop new technologies and improve existing designs. This focus on R&D is crucial for enhancing the functionality and aesthetic appeal of airless bottles, which can lead to increased consumer adoption. In 2025, the overall investment in packaging innovation is projected to exceed $5 billion in the US, indicating a strong commitment to advancing packaging solutions. The airless bottle market stands to benefit from these investments, as enhanced designs can attract a broader customer base and meet evolving consumer preferences.