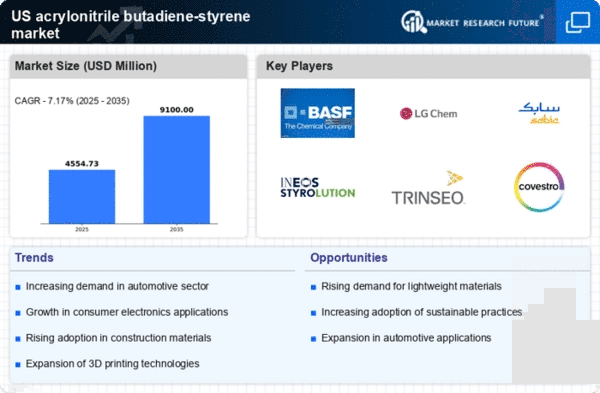

The acrylonitrile butadiene-styrene market is characterized by a competitive landscape that is increasingly shaped by innovation, sustainability, and strategic partnerships. Key players such as BASF SE (Germany), LG Chem Ltd (South Korea), and SABIC (Saudi Arabia) are actively pursuing strategies that enhance their market positioning. BASF SE (Germany) focuses on sustainable production methods, aiming to reduce carbon emissions in its manufacturing processes. Meanwhile, LG Chem Ltd (South Korea) emphasizes technological advancements in polymer production, which allows for enhanced product performance and application versatility. SABIC (Saudi Arabia) is leveraging its extensive The acrylonitrile butadiene-styrene market reach, particularly in emerging economies, thereby enhancing its competitive edge.The market structure appears moderately fragmented, with several players vying for market share. Key business tactics include localizing manufacturing to reduce logistics costs and optimizing supply chains to enhance efficiency. This collective approach by major companies fosters a competitive environment where agility and responsiveness to market demands are crucial. The influence of these key players is significant, as they not only drive innovation but also set industry standards that smaller competitors often follow.

In September BASF SE (Germany) announced a partnership with a leading technology firm to develop a new line of bio-based acrylonitrile butadiene-styrene products. This strategic move is likely to position BASF at the forefront of sustainable materials, appealing to environmentally conscious consumers and industries. The collaboration underscores the growing importance of sustainability in product development and market differentiation.

In October LG Chem Ltd (South Korea) unveiled a new production facility in the U.S. aimed at increasing its output of high-performance acrylonitrile butadiene-styrene. This expansion is expected to enhance LG Chem's ability to meet rising demand in the automotive and electronics sectors, indicating a strategic focus on regional supply chain optimization. Such investments reflect a commitment to maintaining competitive advantage through increased production capacity and localized operations.

In August SABIC (Saudi Arabia) launched a new initiative aimed at integrating AI technologies into its production processes. This initiative is anticipated to streamline operations and improve product quality, thereby enhancing overall efficiency. The adoption of AI signifies a broader trend within the industry towards digital transformation, which is becoming increasingly vital for maintaining competitiveness in a rapidly evolving market.

As of November the acrylonitrile butadiene-styrene market is witnessing trends that emphasize digitalization, sustainability, and technological integration. Strategic alliances among key players are shaping the competitive landscape, fostering innovation and collaboration. The shift from price-based competition to a focus on technological advancements and supply chain reliability is evident. Companies that prioritize innovation and sustainable practices are likely to emerge as leaders in this evolving market.