Market Analysis

In-depth Analysis of Underfill Dispensers Market Industry Landscape

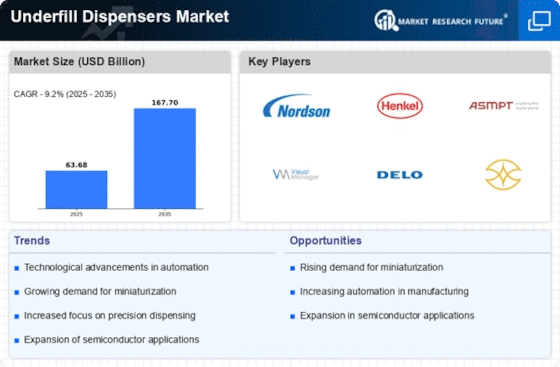

The Underfill Dispensers Market is driven by dynamic and interconnected market dynamics that shape its growth trajectory. One of the key driving forces is the continual evolution of technology in the electronics industry. As electronic devices become smaller and more complex, the demand for precise and efficient underfill dispensers rises. Technological advancements in dispensing mechanisms, materials, and automation contribute to the market's dynamism, enabling manufacturers to meet the evolving needs of electronic components assembly.

Market dynamics are also heavily influenced by the increasing prevalence of miniaturized electronic devices across various industries. The consumer electronics sector, in particular, has witnessed a surge in demand for smaller and more lightweight gadgets. Underfill dispensers play a crucial role in ensuring the reliability and durability of these compact electronic devices, driving their adoption in the market.

The global economic landscape significantly impacts the Underfill Dispensers Market dynamics. Economic growth, industrialization, and investment in research and development activities contribute to the expansion of the market. During periods of economic prosperity, there is a heightened production of electronic devices, leading to an increased demand for underfill dispensers. Conversely, economic downturns can result in a reduction in consumer spending and manufacturing activities, affecting the market negatively.

Regulatory factors also play a pivotal role in shaping market dynamics. The electronics industry is subject to stringent regulations concerning product safety, quality standards, and environmental impact. Compliance with these regulations is essential for market acceptance, and manufacturers need to adapt their products to meet evolving industry standards. Additionally, the increasing emphasis on sustainable and environmentally friendly practices has led to the development of underfill dispensers that align with eco-friendly standards, influencing market dynamics.

Competition among key players is a significant aspect of market dynamics. The Underfill Dispensers Market is characterized by intense competition, with companies vying for market share through innovation, product differentiation, and strategic collaborations. Continuous investment in research and development is crucial for companies to stay ahead of the competition and introduce advanced features and functionalities.

Geographical factors contribute to the varied dynamics within the underfill dispensers market. The distribution of manufacturing facilities, technological capabilities, and the presence of key end-user industries vary across regions. As a result, the demand for underfill dispensers is not uniform globally. Emerging economies with a thriving electronics manufacturing sector often experience higher growth rates compared to more developed regions.

Market dynamics are also influenced by the shift towards Industry 4.0 and smart manufacturing practices. Automation and the integration of advanced technologies in manufacturing processes enhance efficiency and accuracy, driving the demand for automated underfill dispensers. Manufacturers are increasingly adopting smart manufacturing solutions to streamline production, reduce errors, and improve overall productivity.

Leave a Comment