- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

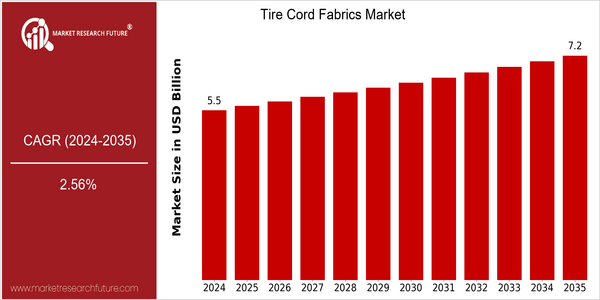

Tire Cord Fabrics Market Size Snapshot

| Year | Value |

|---|---|

| 2024 | USD 5.45 Billion |

| 2035 | USD 7.2 Billion |

| CAGR (2025-2035) | 2.56 % |

Note – Market size depicts the revenue generated over the financial year

The tire cord fabric market is expected to reach USD 5.45 billion in 2024, and reach USD 7.2 billion in 2035. This growth represents a compound annual growth rate (CAGR) of 2.6% from 2025 to 2035. The main reasons for this expansion are the increasing demand for high-performance tires, the development of tire manufacturing technology, and the development of the automobile industry in emerging economies. The increasing demand for durable and lightweight tire cord fabrics is also driving the development of the tire cord fabric industry, which will drive the industry to develop and increase investment. The major players in the tire cord fabric market, such as Continental AG, Teijin Limited, and Kordsa Teknik Tekstil A.S., are also actively involved in strategic cooperation and development to enhance their market share. They are mainly developing advanced tire cord fabrics with better performance and higher degree of recyclability. Research and development of green tire cord fabrics is in line with the trend of industry development towards a circular economy. This not only strengthens the competitiveness of the company, but also meets the needs of consumers.

Regional Deep Dive

The Tire Cord Fabrics Market is experiencing a dynamic growth in the regions across the globe, owing to the growing demand for automobiles, increasing demand for fuel-efficient vehicles, and the technological advancements in the tire industry. The Tire Cord Fabrics Market is characterized by the unique characteristics of the regions based on the local manufacturing capabilities, regulatory frameworks, and consumer preferences. North America and Europe are focusing on innovation and sustainable growth, while Asia-Pacific is experiencing a rapid industrialization and urbanization, which is expected to have a significant impact on the demand for tire cord fabrics. The Middle East and Africa are gradually developing their auto industries, while Latin America is experiencing a revival in the tire industry, owing to the economic recovery and the investment in the transportation network.

North America

- In the United States, the tire industry is shifting towards the use of sustainable materials. Continental and Goodyear are investing in the development of tire fabrics made from natural materials to meet the new requirements of the authorities and the wishes of consumers.

- A recent increase in import tariffs on tire cord fabrics has led domestic manufacturers to increase their production capacity, thus boosting domestic investment and the development of new products.

- North America's growing EV market is influencing the development of tires and their materials. Companies like Tesla and Rivian are collaborating with tire cord fabric producers to develop new, more efficient tire fabrics.

Europe

- Moreover, the European Union’s stricter regulations on exhaust gasses are forcing tire-makers to adopt new fibres, which are lighter, more economical, and less harmful to the environment. Michelin is at the forefront of these developments.

- There is also a development in the area of smart tires. Bridgestone has developed a tire cord fabric with sensors that can monitor tire performance and health in real time.

- The European market is seeing a greater co-operation between the automobile industry and the textile industry to produce a high-performance tire cord fabric for high-performance and luxury vehicles.

Asia-Pacific

- China is still the largest manufacturer of tire cord fabric, and its tire cord factory has been continuously improved in automation and technology, and its product quality has been further improved.

- The growing motor industry in India has created a demand for tyre cord fabrics, and to meet this demand Apollo Tyres is expanding its production capacity.

- Governments of Japan and Korea are encouraging the development of new materials for tires and tire cord fabrics.

MEA

- The Middle East is gradually developing its car industry, and the United Arab Emirates is investing in tire production. This will boost the demand for tire cord fabric in the Middle East.

- The new laws for the improvement of the road safety have made it necessary to seek higher quality cords for the tires, which has led to the establishment of new associations with the foreign suppliers.

- The increasing popularity of electric vehicles in the region is influencing the design of tires. Tire manufacturers are looking for new materials and new technologies to improve performance and the environment.

Latin America

- Brazil is becoming an important player in the tire cord fabrics market, with the expansion of local production, mainly for the domestic market, but also for export, supported by government incentives.

- The use of reclaimed rubber in tire cords is a growing trend in the region, prompted by both the consumers’ demand for a sustainable product and the regulatory pressure to reduce waste.

- Latin America’s growing demand for commercial vehicles is expected to drive the demand for high-quality tire cord fabric.

Did You Know?

“It is said that about seventy per cent of the quality of a tire depends upon the quality of the cords used in it, and that it is therefore a most important constituent of the tire.” — Tire Industry Association

Segmental Market Size

The Tire Cord Fabrics segment plays a crucial role in the tire industry. The main purpose of this segment is to provide reinforcements that increase the strength and life of the tire. This segment is currently experiencing a stable growth, mainly driven by the increasing demand for high-performance tires in the automobile industry. There are several reasons for this. The first is that the demand for safety and performance is increasing. The second is that the government is implementing stricter regulations in order to improve the fuel economy of vehicles and reduce harmful emissions.

The use of advanced tire fabrics has now reached a point where Continental and Michelin are leading the way in their development. These fabrics are mainly used in the production of tires for passenger cars, commercial vehicle tires, and special tires for off-road use. These are the markets that are the most important. Among the trends that are expected to boost growth are the sustainable development goals, which are expected to increase the focus on eco-friendly materials and production processes. These developments are based on new weaving techniques and smart textiles, which are enabling the development of lighter, stronger, and more efficient tire fabrics.

Future Outlook

From 2024 to 2035, the tire cord fabric market is expected to grow at a CAGR of 3.16%. The increase in the demand for high-performance tires is due to the growing trend toward electric vehicles and the increased requirements for fuel efficiency. The use of advanced synthetic fibers in tire cord fabrics is expected to increase significantly, and by 2035, the penetration rate in the premium tire segment will reach more than 60%.

This report is based on an extensive investigation of the global tire cord industry. The report highlights the technological developments, such as the development of eco-friendly tire cord materials and the introduction of advanced tire cord production processes. The development of smart textiles and the Internet of Things is expected to enhance the performance of tire cord fabrics, such as wear resistance and safety. Government initiatives to reduce carbon emissions and promote sustainable development in the auto industry will also create a favorable environment for market development. The report also analyzes the trend of the development of tire cords, such as the popularity of retreading and the circular economy.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Growth Rate | 3.9% (2022-2030) |

Tire Cord Fabrics Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.