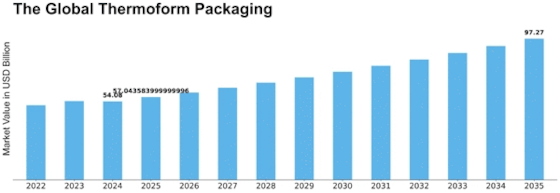

Thermoform Packaging Size

Thermoform Packaging Market Growth Projections and Opportunities

The play of many factors sets the dynamics of the thermoform packaging popularity growth. Among the most prominent factors, termoscalfo pack products’ high demand from different class of industries is one. Thermoplastic packaging process is favorable as it is able to package products in a dedicated manner and wide variety of items like food, medical, electric equipment and consumer goods are to be packaged. In the era of the evolving lifestyles and preferences of consumers, the package design has become more integrated into the functions and forms of consumer goods consequently, the thermoform packaging is evolving to be a more common and convenient packaging solution.

Besides that, sustainable packaging practices are proving as a significant influence on the thermoform packaging market competitive environment. Keeping an eye on the rise of environmental issues, not only consumers but businesses are looking for (packing) materials which are eco-friendly and minimize the impact they take on the environment. Thermo form packaging being more capable of using recyclable materials and thin designs pops up amid sustainability trends. lots of plastic packaged manufacturers from the thermoforming packaging market are making arrangements for research and development to invent novel, environmental-friendly packaging solutions in tune with the evolving tastes of consumers and in compliance with regulatory rules.

Advanced technology is also a major driver as technology advances tend to influence the growth in this industry. Automation plus technologically high level machines and equipments in thermoforming process improves performance, lowers production costs and ensures good quality. Similarly, technological discoveries lead to inventing new, improved and reinforced thermoform packaging materials characterized by exceptional barrier properties, shelf life extension, and flexibility in customization. The technological advancements help not only manufacturers to enhance their systems but also serve the consumers with the assistive packages that could impact their needs of market in a dynamic way.

Along with the economic conditions and the dynamics of trade, there is a bundle of other factors that influence the thermoform packaging market. The shift in currency exchange rates, political and trade issues might impact the procurement costs of the essential inputs which is the production cost for the manufacturers A good health and a solid economic growth in the significant markets around the world ensure more consumption and subsequently more demand for the need of such kind as thermoform packaging which mean a positive effect on the productivity market. Conversely, Economic slowdowns or a prevalent sense of uncertainty might results to a temporary drop in market growth —while businesses doing hard thinking in their spending and investment plans.

Customer's predilections and buying habits are amongst the major factors that generate the thermoform packaging market. With a growing number of people being health-conscious and cared about the environment, therefore, there arises a trend of how the packaging methods are used to enhance the safety and freshness of product for as well as minimize negative impact on the environment .

Leave a Comment