Thermal Spray Coatings Size

Thermal Spray Coatings Market Growth Projections and Opportunities

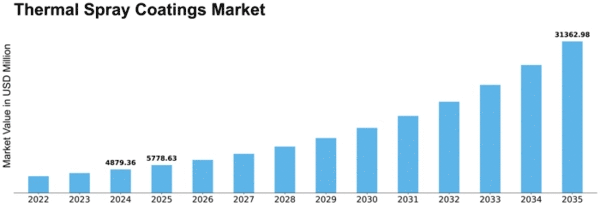

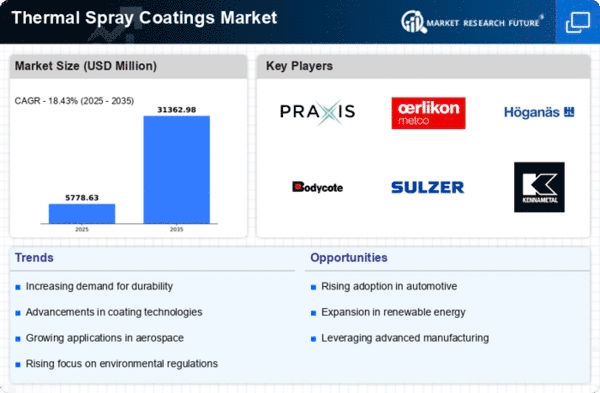

The Thermal Spray Coatings market is influenced by a number of market factors that collectively shape its dynamics. One of the pivotal factors driving the market is the increasing demand for protective coatings in diverse industries. Thermal spray coatings are preferred because they enhance material durability and performance under harsh conditions. As the aerospace, automotive, and energy industries continue to grow, there will be a need for reliable and robust protective coatings, which will lead to the expansion of thermal spray coatings in these markets. By 2028, the Thermal Spray Coatings Market is projected to generate revenue worth $10.7 billion while achieving a global CAGR of 7% for the forecast period ending 2028. Furthermore, technological advancements remain an important factor in determining the market landscape. This is reflected through continuous advancements in thermal spray coating technologies, materials, and application processes, which contribute to market development. Manufacturers and researchers are developing coatings with better features such as wear-resistance improvement protection against corrosion as well as offering good insulation properties. These regulations have enhanced sustainability awareness among various nations globally, thus influencing the choice of thermal spray coating industry products into more environmentally friendly options that can help safeguard them from these changes. Economic aspects influence market dynamics, with overall economic conditions within regions being paramount variables. Economic growth causes industrial activities to increase, thus stimulating demand for thermal spray coatings. Besides this, globalization and international trade also affect where the thermal sprays are sold for use across borders, bringing about dynamic changes within this field due to other reasons involved, such as politics or culture between different countries around the globe, affecting their success rates when coming into contact with one another's systems too heavily involved here since they have been affected negatively at times due not only environmental laws but also those concerning team member health & safety standards; hence affecting what types of paints should be employed where – even though most often stringent regulations require certain kinds used instead over others depending upon geographical location, etc.; lastly competitive landscapes as well mergers and acquisitions can be attributed to most if not all these reasons.

Leave a Comment