Super Abrasives Size

Super Abrasives Market Growth Projections and Opportunities

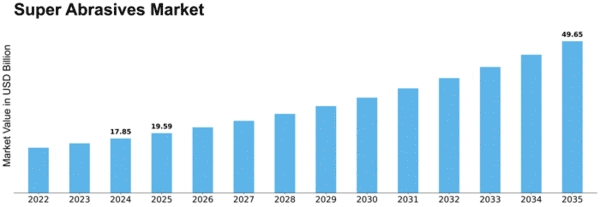

The super abrasives market is estimated to have grown at a CAGR of 6.78 percent to USD 14.45 billion during the forecast 2021-2030.

The super abrasives market is shaped by various factors that collectively influence its dynamics. One primary driver is the growing demand across industries for precision grinding tools that offer exceptional hardness and durability. Super abrasives, such as diamond and cubic boron nitride (CBN), are extensively used in manufacturing processes for cutting, grinding, and polishing applications in sectors like automotive, aerospace, and electronics. The unique properties of super abrasives, including high hardness and thermal stability, contribute significantly to their adoption, impacting the overall super abrasives market.

Technological advancements and innovations in super abrasives play a pivotal role in driving market growth. Continuous research and development efforts focus on enhancing the performance and efficiency of super abrasive tools, exploring new applications, and developing cost-effective manufacturing methods. Innovations in bond systems, abrasive particle designs, and manufacturing techniques contribute to the development of high-performance super abrasives that meet the evolving needs of different industries. Manufacturers strive to offer solutions that enhance precision and productivity in various machining processes.

The global economic landscape significantly influences the super abrasives market. Economic growth often leads to increased manufacturing activities, driving the demand for high-precision tools like super abrasives. Conversely, economic downturns may impact certain industries, affecting the demand for super abrasives. The market's sensitivity to economic fluctuations underscores the importance of monitoring global economic trends for stakeholders in the super abrasives industry.

Regulatory considerations and standards also play a crucial role in shaping the super abrasives market. Due to their use in critical manufacturing processes, super abrasives are subject to regulations concerning workplace safety, environmental impact, and compliance with industry standards. Meeting these regulatory requirements is essential for super abrasives manufacturers to ensure market acceptance and meet the expectations of consumers and regulatory authorities.

Raw material availability and pricing are critical considerations in the super abrasives market. The primary raw materials for super abrasives, such as diamond and CBN, are sourced from natural or synthetic origins. Fluctuations in the prices and availability of these raw materials can impact the overall production cost of super abrasives. Manufacturers closely monitor raw material markets to adjust their strategies and maintain cost-effectiveness in the competitive market.

Geographical factors also play a role in shaping the super abrasives market. Different regions may have varying levels of industrialization, manufacturing activities, and infrastructure development, influencing the demand for super abrasives. Areas with a strong presence in precision machining and advanced manufacturing may experience higher demand for super abrasives products.

Environmental considerations are increasingly influencing the super abrasives market. As industries strive to adopt more sustainable practices, there is a growing focus on developing eco-friendly super abrasives and sustainable manufacturing processes. Manufacturers are exploring ways to enhance the environmental profile of super abrasives, including the use of recycled materials, responsible sourcing, and reducing the environmental impact of production.

Health and safety considerations also play a role in the super abrasives market, particularly concerning workplace exposure to abrasive particles during manufacturing processes. Occupational safety standards and regulations impact production practices and worker safety in industries utilizing super abrasives. Compliance with these health and safety standards is essential for super abrasives manufacturers to ensure a safe working environment and meet regulatory requirements.

Leave a Comment