Stainless Steel Fermenter Size

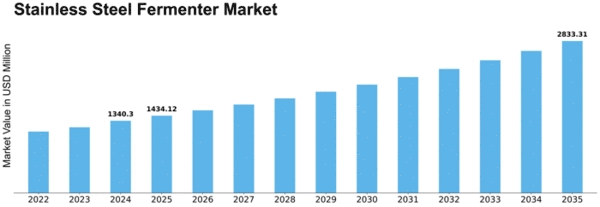

Stainless Steel Fermenter Market Growth Projections and Opportunities

The market for stainless steel fermenter is affected by progressions in innovation, plan, materials, and computerization. Fermenter creation has been changed by these adjustments, bringing about mechanical assembly that is more exact, versatile, and productive. Different ventures require hardened steel fermenters with capabilities like temperature transformation, computerized controls, checking frameworks, and adaptable plans, which animates interest for these materials. The market for stainless steel fermenters is moulded by the growing interest in enterprises like food and refreshment, biotechnology, drugs, and exploration establishments, which depend on aging cycles to deliver biofuels, biopharmaceuticals, and immunizations, among others. The stainless steel fermenter industry is laid out through the improvement of erosion opposition, sturdiness, and adherence to industry norms like GMP and FDA rules. This ensures the development of top caliber, consistent fermenters that track down broad use in different modern areas. Cleanliness and manageability are basic variables in the tempered steel fermenter industry, considering that the recyclability, erosion obstruction, and sturdiness of steel are reliable with practical assembling processes. This is reliable with the developing prerequisite for environmental fermenters. The market is affected by globalization, vital organizations, and market combination, with noticeable industry members teaming up to improve mechanical capacities and expand item contributions. Customization and adaptability are the essential elements impacting the interest for treated steel fermenters, considering that makers give adaptable answers for oblige assorted group sizes, aging methods, and industry prerequisites. The market elements of these fermenters are prominently affected by their customization, secluded plans, and functional adaptability, which ensures that they can actually take care of the changing necessities of assorted businesses. Various elements impact the tempered steel fermenter market, including new innovations, industry interest, fabricating headways, an accentuation on manageability and cleanliness, serious methodologies, and customization. Innovative headways, growing applications, manufacture procedures, naturally ideal and clean practices, market techniques, and modified arrangements all impact the market's elements. The continuous advancement and creativity in these spaces impel the assembling and utilization of treated steel fermenters, laying out them as basic instruments in a huge number of modern cycles that depend on maturation. The extension and advancement of the market are essential to the outcome of these clever items.

Leave a Comment