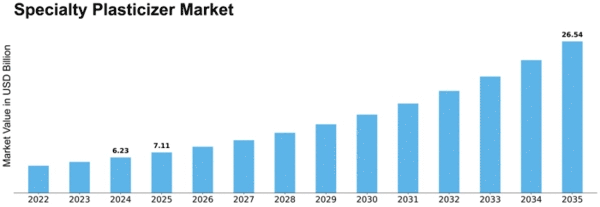

Specialty Plasticizer Size

Specialty Plasticizer Market Growth Projections and Opportunities

The Specialty Plasticizer market is influenced by several factors that collectively shape its dynamics. One of the primary determinants is the increasing demand for specialty plasticizers across various industries, such as construction, automotive, and consumer goods. Specialty plasticizers, known for their ability to enhance the flexibility and durability of plastics, find widespread use in applications like cables, flooring, and medical devices. The growth of end-use industries, driven by factors like population growth, urbanization, and technological advancements, directly impacts the demand for specialty plasticizers.

Raw material dynamics play a crucial role in the specialty plasticizer market. The primary raw materials for specialty plasticizers include phthalic anhydride, adipic acid, and trimellitic anhydride, among others. Any fluctuations in the supply and pricing of these key components can affect the overall production costs of specialty plasticizers. Factors such as changes in feedstock prices, market demand for raw materials, and geopolitical events influencing the supply chain can lead to price volatility in the specialty plasticizer market.

Stringent regulatory standards and environmental considerations significantly shape the specialty plasticizer market. With increasing awareness of environmental issues, there is a growing emphasis on the use of non-phthalate and bio-based plasticizers to mitigate potential health and environmental risks associated with traditional plasticizers. Regulatory measures restricting the use of certain plasticizers, such as phthalates, drive the demand for alternative specialty plasticizers that comply with safety and environmental standards. Companies that proactively develop and market eco-friendly specialty plasticizers position themselves favorably in a market where sustainability is gaining prominence.

Technological advancements contribute significantly to the evolution of the specialty plasticizer market. Ongoing innovations in plasticizer formulations and manufacturing processes aim to enhance performance characteristics, improve compatibility with various polymers, and address specific application requirements. Companies that invest in research and development to introduce high-performance and application-specific specialty plasticizers gain a competitive edge in a market where customization and versatility are valued.

Global economic conditions and industrial trends are pivotal in shaping the specialty plasticizer market. Economic factors such as GDP growth, industrial production, and construction activities influence the overall demand for plastics and, consequently, specialty plasticizers. Changes in consumer preferences, lifestyle trends, and advancements in end-use applications contribute to the market dynamics, making it essential for specialty plasticizer manufacturers to stay attuned to broader economic trends and industry developments.

Market competition is a constant consideration in the specialty plasticizer sector. The presence of multiple players, each offering a variety of specialty plasticizers for different applications, intensifies competition. Companies differentiate themselves through factors such as product quality, innovation, pricing strategies, and customer service. Mergers, acquisitions, and strategic partnerships are common strategies employed by companies to strengthen their market position, expand their product portfolios, and enhance their global reach.

Consumer preferences and industry trends also contribute to the specialty plasticizer market's evolution. Changing preferences for sustainable and environmentally friendly products, as well as advancements in polymer technologies, influence the demand for specific types of specialty plasticizers. Companies that anticipate and adapt to these trends are better positioned to meet market demands effectively and capitalize on emerging opportunities.

Leave a Comment