Specialty Elastomers Size

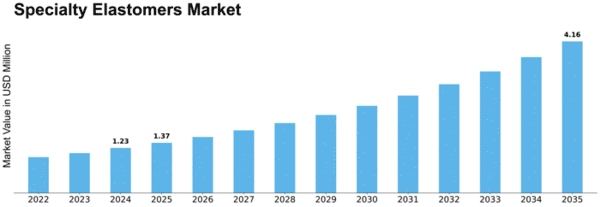

Specialty Elastomers Market Growth Projections and Opportunities

The specialty elastomer market is subjected to a range of factors that collectively define its dynamics and growth patterns. An important force within the field is the increasing use in these sectors of specialized elastomeric materials characterized by unique characteristics. Specialty elastomers find extensive applications in automotive, healthcare, electronics and industrial sectors, due to their exceptional heat-resistance, chemical resistance and ability to withstand harsh climatic conditions. Their versatility in meeting specific requirements like high-performance sealing or insulation makes them critical for a broad scope of manufacturing processes.

Additionally, the specialty elastomer market is significantly shaped by the automotive industry. In this case, specialty elastomers are increasingly being used to make seals and gaskets among other components as manufacturers seek lighter weight cars that are more fuel efficient. Moreover, within the automotive sector; these materials have long life cycles that are necessary for withstanding tough operating conditions.

Environmental considerations also weigh heavily on the specialty elastomer market. Such regulatory standards emphasizing reductions in carbon footprints as well as use of environmentally friendly materials further determine market trends. Therefore, manufacturers are involved in R&D activities aimed at meeting such eco-conscious calls through development of speciality elastomers.

Another factor affecting the specialty elastomer industry is global economic landscape changes. Prices of raw material fluctuations affect production costs and market competitiveness due to trade policies changeability or geopolitical tensions. For instance, business people always keep an eye on economic tendencies so they can be aware hence safe from cost volatility-related problems.

The specialist elastomer sector is driven by technological advances as well. This way ongoing researches promote new hydrogels with enhanced performance characteristics such as increased flexibility, better weathering resistance and superior low temperature properties. Apart from addressing changing end-user preferences & tastes; this move will boost the competitiveness of this market.

Additionally, competitive landscape affects the specialty elastomer market through strategic alliances, mergers and acquisitions among major industry players. Strategic alliances enable companies to pool resources, share expertise and expand their product portfolio in the market. These are some of the strategic moves that improve a firm’s market position for overall growth and development of specialty elastomers.

Also, consumer tastes as well as trends control the specialty elastomer market. As end-users increasingly demand products with improved performance, durability, and sustainability, manufacturers must align their offerings with these evolving expectations. Furthermore, customization options, innovative solutions and adherence to industry trends contribute towards enhancing success rates of such specialty elastomers within a fiercely fought over marketplace."

Leave a Comment