Sheet Metal Size

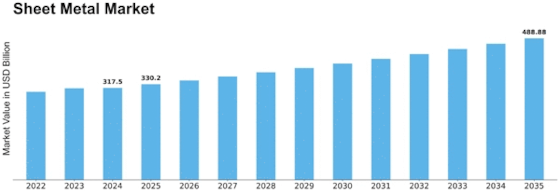

Sheet Metal Market Growth Projections and Opportunities

The sheet metal market is influenced by various market factors that shape its dynamics and growth trajectory. One crucial factor is the demand-supply balance, which is driven by the construction, automotive, aerospace, and manufacturing industries' needs. Economic conditions, such as GDP growth, interest rates, and inflation rates, also play a significant role in determining the demand for sheet metal products. During periods of economic expansion, there's typically higher demand for sheet metal due to increased construction and manufacturing activities. Conversely, during economic downturns, demand may decrease as businesses cut back on expenses.

Technological advancements are another critical factor shaping the sheet metal market. Innovations in manufacturing processes, such as laser cutting, CNC machining, and 3D printing, have enhanced efficiency, accuracy, and customization capabilities in sheet metal fabrication. These advancements not only improve productivity but also enable manufacturers to offer a wider range of products to meet diverse customer needs.

The combination of different metal elements leads to the formation of sheet metal. Elements of metal ingots, billets, and blooms to slim and stretchable pieces on the application of different industrial processes lead to the formation of the sheet market.

Raw material prices and availability heavily influence the sheet metal market. Metals like steel, aluminum, and copper are the primary materials used in sheet metal fabrication. Fluctuations in the prices of these raw materials can impact production costs and ultimately affect product pricing and profitability for manufacturers. Additionally, factors like geopolitical tensions, trade policies, and environmental regulations can disrupt the supply chain and affect material availability.

Consumer preferences and industry trends also drive market factors in the sheet metal industry. For example, the growing emphasis on sustainability and environmental responsibility has led to increased demand for eco-friendly materials and production processes. As a result, manufacturers are adopting recycled metals and implementing energy-efficient manufacturing practices to align with these preferences and stay competitive in the market.

Globalization has a significant impact on the sheet metal market, as manufacturers face competition from both domestic and international players. Market globalization opens up opportunities for expansion into new markets but also intensifies competition, leading to pricing pressures and the need for continuous innovation and efficiency improvements to maintain a competitive edge.

Regulatory factors, including safety standards, environmental regulations, and trade policies, also shape the sheet metal market. Compliance with regulatory requirements is essential for manufacturers to ensure product quality, safety, and environmental sustainability. Changes in regulations can impact production processes, product design, and market access, requiring companies to adapt and invest in compliance measures.

Market trends and forecasts also influence the sheet metal market, as businesses and investors rely on market analyses and projections to make informed decisions. Factors such as population growth, urbanization, and infrastructure development drive long-term demand for sheet metal products, while emerging technologies and shifting consumer preferences introduce new opportunities and challenges for industry players.

Leave a Comment