- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

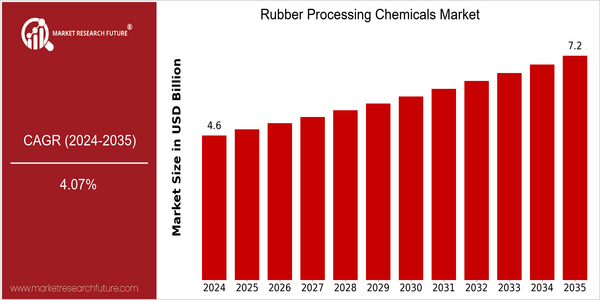

Rubber Processing Chemicals Market Size Snapshot

| Year | Value |

|---|---|

| 2024 | USD 4.64 Billion |

| 2035 | USD 7.2 Billion |

| CAGR (2025-2035) | 4.07 % |

Note – Market size depicts the revenue generated over the financial year

The rubber-processing chemicals market is expected to grow at a steady rate, from a current value of $ 4,644 million in 2024 to $ 7,244 million by 2035. A CAGR of 4.07 percent is projected for the period 2025 to 2035. The market is driven by a number of factors, including the rising demand for rubber in various end-use industries such as the automobile, construction and consumer goods industries, which has led to the need for rubber-processing chemicals to enhance the performance and service life of rubber products. Technological developments in the rubber-processing industry, such as the development of high-performance and eco-friendly rubber-processing chemicals, are also contributing to market growth. The rising emphasis on sustainable development by companies has led to the development of bio-based rubber-processing chemicals. The major players in the market, such as BASF, Lanxess and Eastman, are focusing on strategic initiatives such as collaborations and research and development to enhance their product offerings and capture a larger market share. These efforts not only address the increasing focus on the environment but also meet the growing demand from consumers for sustainable products.

Regional Deep Dive

The rubber-processing chemicals market is undergoing a dynamic expansion in many regions, mainly driven by the increasing demand from the automobile, construction, and consumer goods industries. In North America, the market is characterized by innovation and sustainable development, with companies focusing on the development of rubber-processing chemicals that are more eco-friendly. Europe is characterized by the strict implementation of regulations, which encourages the use of advanced materials. Asia-Pacific is characterized by rapid industrialization and urbanization, which are driving the demand for rubber products. Middle East and Africa are characterized by an increase in investments in the construction industry, which drives the market for rubber-processing chemicals, and Latin America is gradually adopting advanced rubber-processing technology, which further boosts the market.

North America

- The EPA has imposed stricter regulations on chemical emissions, and companies such as Eastman have been developing new, low-emission rubber chemicals.

- This is why BASF is investing in the development of new rubber chemicals based on biomaterials.

- The change to electric cars is driving the demand for special rubber compounds, which in turn is leading to higher R&D expenditure on the development of high-performance rubber-processing chemicals.

Europe

- The REACH regulation is also affecting the rubber chemicals market. It requires manufacturers to register and evaluate the safety of their chemicals. This leads to increased transparency and more innovation in product development.

- Lanxess is developing special rubber processing chemicals that increase the performance and the life of tires, which is in keeping with the region's focus on sustainability and performance.

- The rising importance of the European circular economy has led to the development of new rubber processing techniques and chemicals that facilitate the recyclability of rubber.

Asia-Pacific

- The belt and road initiative will drive the construction of roads, railways and ports in the region, boosting the demand for rubber products and, in turn, for rubber chemicals.

- Apollo Tyres is investing in new technology to meet the increasing demand for rubber.

- Japanese research institutions are studying new smart rubber processing chemicals, such as self-healing materials, which can greatly enhance the life and performance of products.

MEA

- The UAE Vision 2021, with its emphasis on sustainable development, has led to a greater investment in rubber chemicals for the construction and automobile industries.

- The program of development of industry and trade, which is aimed at promoting the national industry and reducing the dependence on foreign trade, is helping the development of the rubber industry.

- The unique climate of the area has made it necessary to manufacture rubber products that are suited to the climate. The companies are thus experimenting with new chemicals to improve the properties of rubber in extreme heat.

Latin America

- Brazil’s growing automobile industry is boosting the demand for rubber processing chemicals. So domestic companies like Braskem are investing in the development of bio-based alternatives to traditional chemicals.

- In the midst of the growing demand for rubber, the rubber industry is adopting the use of rubber-friendly chemicals, backed by government initiatives aimed at reducing the impact on the environment.

- Latin America, with its new rubber-processing industries, is gradually modernizing its rubber industry, and bringing in new technology and new skills.

Did You Know?

“The fact that over seventy per cent of rubber-processing chemicals are used in the manufacture of tyres shows the importance of this industry in the creation of demand.” — International Rubber Study Group (IRSG)

Segmental Market Size

The rubber processing chemicals industry is a vital industry, playing a vital role in improving the performance and the service life of rubber products. It is currently growing steadily. The main demand drivers are the rising car production, which calls for high-quality rubber parts, and the rising demand for environment-friendly rubber processing chemicals. In addition, the government's policy to limit harmful emissions is driving the industry to develop advanced rubber processing chemicals that meet the standards.

In the rubber industry, the use of chemicals for processing rubber has already reached a stage of maturity. The leading companies such as BASF and Lanxess are investing heavily in R&D to develop new products and improve performance. The main application areas are tires, where certain chemicals improve grip and life, and industrial rubber products such as seals and gaskets, which require high wear resistance. The trend towards electric mobility and the drive for sustainability are causing a further increase in demand as manufacturers try to meet the new requirements while reducing the impact on the environment. Nanotechnology and bio-based chemicals are enabling the development of superior rubber formulations.

Future Outlook

The rubber industry is growing at a rapid pace. The rubber industry is expected to grow from $ 4.64 billion in 2024 to $ 7.08 billion by 2035, with a CAGR of 4.07 percent. The rubber industry is mainly driven by the rising demand for rubber from the automotive, construction and consumer goods industries. As the world economy grows, the demand for high-quality rubber products will increase, which will drive the demand for rubber chemicals. By 2035, rubber chemicals will account for about 11.8 percent of the total rubber production, indicating a strong integration of rubber chemicals into rubber production.

This is a report on the rubber chemicals market. Green and sustainable rubber processing chemicals are expected to be developed in the future, and the trend of promoting green products is expected to be followed. The rise of electric vehicles and the development of tire technology will further drive the demand for specialized rubber chemicals that can improve the performance and life of rubber. The development of smart manufacturing and the trend of Industry 4.0 will also help rubber companies to improve the efficiency and effectiveness of rubber production, so as to meet the market's new demands and meet the increasingly stricter environment requirements.

Rubber Processing Chemicals Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.