Market Trends

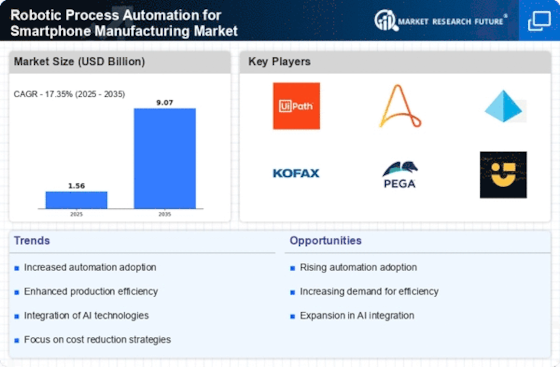

Key Emerging Trends in the Robotic Process Automation for Smartphone Manufacturing Market

Examining the trends in Robotic Process Automation (RPA) for smartphone manufacturing reveals a transformative landscape shaped by technological advancements and industry demands. RPA is playing a pivotal role in streamlining manufacturing processes for smartphones. One notable trend is the increased adoption of robotic automation in assembly lines, where robots are efficiently handling tasks such as component placement, soldering, and quality control. This not only enhances precision and speed but also contributes to cost reduction by minimizing errors and increasing overall efficiency in smartphone production.

Another trend in the smartphone manufacturing industry is the integration of RPA in supply chain management. Automation technologies are being leveraged to optimize inventory management, order processing, and logistics. RPA ensures real-time data analysis, allowing manufacturers to make informed decisions and respond swiftly to market demands. This trend is driven by the need for agility and flexibility in the supply chain, enabling smartphone manufacturers to adapt quickly to changes in consumer preferences and market dynamics.

Additionally, the application of RPA in quality control processes is gaining prominence in smartphone manufacturing. Automation technologies are being deployed to conduct thorough inspections, detect defects, and ensure the adherence to stringent quality standards. This not only enhances the overall product quality but also reduces the likelihood of manufacturing defects and recalls. As the smartphone market continues to evolve with constant innovations and rising consumer expectations, the integration of RPA trends in manufacturing processes is expected to play a crucial role in ensuring efficiency, precision, and competitiveness in the industry.

Leave a Comment