Resistance Alloys Size

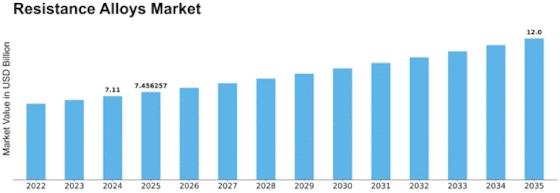

Resistance Alloys Market Growth Projections and Opportunities

The Resistance Alloys Market is influenced by a variety of market factors that collectively contribute to its growth and dynamics. One of the primary drivers is the demand from industries that require materials with specific electrical and thermal resistance properties. Resistance alloys, characterized by their ability to resist the flow of electric current and withstand high temperatures, find extensive use in heating elements, electrical appliances, and industrial equipment. The electrical and thermal conductivity of these alloys makes them essential in applications where controlled resistance and durability are crucial, contributing to the steady demand in the market.

Technological advancements in metallurgy and alloy formulations significantly contribute to market dynamics. Continuous research and development efforts focus on improving the performance, efficiency, and cost-effectiveness of resistance alloys. Innovations in alloy compositions, heat treatment methods, and manufacturing processes enhance the overall properties of resistance alloys, expanding their applications across various industries. Technological advancements drive the adaptation of new and improved resistance alloys in emerging sectors and evolving industrial applications.

The electronics and electrical appliances industry's growth further propels the Resistance Alloys Market. As electronic devices become more sophisticated and energy-efficient, the demand for resistance alloys in components like heating elements, resistors, and electrical connectors continues to rise. The surge in the production of consumer electronics, coupled with the expansion of smart home technologies, contributes to the increased utilization of resistance alloys in the manufacturing of various electronic devices.

Global economic conditions and trade dynamics impact the Resistance Alloys Market. As resistance alloys are traded globally, factors such as international trade agreements, tariffs, and geopolitical events can influence the supply chain and market conditions for these alloys. Economic stability, manufacturing trends, and trade policies play a role in determining the accessibility and cost competitiveness of resistance alloys in the market.

Environmental considerations and regulatory standards also play a role in shaping the resistance alloys market. Compliance with environmental regulations ensures that the production and use of resistance alloys adhere to stringent standards. The industry's commitment to environmentally responsible manufacturing processes contributes to its acceptance in various applications where sustainability is a priority.

Market competition and industry collaborations are notable factors shaping the Resistance Alloys Market. The market comprises a mix of established alloy producers, manufacturers, and emerging players, fostering a competitive landscape. Collaboration between resistance alloy producers, end-users, and research institutions facilitates the development of new alloy formulations, innovative applications, and industry standards. Partnerships within the industry supply chain contribute to the overall growth and advancement of resistance alloy solutions.

Challenges related to raw material availability, price volatility, and customization requirements are factors that the resistance alloys industry addresses. The prices of key raw materials, such as nickel, chromium, and iron, can be subject to fluctuations based on market conditions and global supply chain dynamics. Customization requirements for specific applications demand a flexible manufacturing approach, posing challenges in maintaining cost-effectiveness and meeting diverse industry needs. The industry's ability to navigate these challenges contributes to the overall resilience of the resistance alloys market.

Leave a Comment