Top Industry Leaders in the Rare Earth Recycling Market

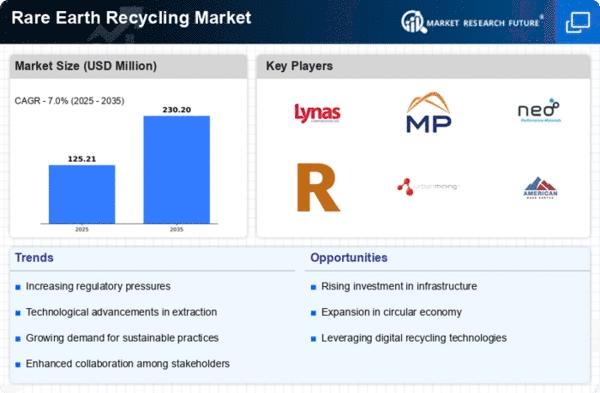

Rare Earth Recycling Market

Rare earth elements (REEs) are critical for various high-tech applications, driving their global demand. However, REE mining and extraction can be ecologically damaging, emphasizing the need for sustainable alternatives. This has led to the rise of the rare earth recycling market, offering a more environmentally conscious solution. This article delves into the competitive landscape of this burgeoning market, exploring key players, strategies, market share factors, industry news, and recent developments.

Strategies Employed by Key Players:

-

Investment in Technology and Innovation: Leading players like Solvay, Hitachi Metals, and Umicore are heavily investing in research and development to optimize their recycling processes and improve efficiency. This includes exploring novel technologies like hydrometallurgical and biohydrometallurgical methods that offer cleaner and more resource-efficient separation of rare earth metals. -

Formation of Strategic Partnerships: Collaboration between mining companies, technology providers, and recyclers is becoming increasingly crucial to gain access to feedstock, expertise, and market reach. For instance, American Rare Earth partnered with GE Renewable Energy to develop a closed-loop recycling system for magnets used in wind turbines. -

Focus on Expanding Geographic Reach: Players are strategically expanding their operations to tap into new markets and secure access to diverse sources of feedstock. For example, Solvay has established recycling facilities in Europe and China, while Lynas is looking to expand its operations in Australia. -

Development of Recycling Infrastructure: Building robust recycling infrastructure is essential to support the growing volume of end-of-life products. Companies are investing in constructing new facilities and upgrading existing ones to improve processing capacity and meet stringent environmental regulations.

Factors Influencing Market Share:

Several factors determine a company's success in the competitive landscape of the rare earth recycling market:

-

Technology Adoption: Companies with advanced and cost-effective recycling technologies gain a significant advantage in terms of efficiency and profitability. -

Feedstock Availability: Access to a reliable and secure source of end-of-life materials is crucial for ensuring consistent production and meeting market demand. -

Financial Strength: Companies with strong financial resources can invest in research and development, expand operations, and compete effectively in the market. -

Regulatory Compliance: Adherence to environmental regulations and sustainability standards is essential for building a positive reputation and gaining market trust.

Key Players

Key players operating in the global rare earth recycling market include Solvay (Belgium), Hitachi Metals (Japan), REEcycle, Inc. (US), Jiangsu Huahong Technology Co., Ltd (China), Lynas (Malaysia), GanZhou QianDong Rare Earths Group Co., Ltd (China), Mitsubishi Chemical Corporation (Japan), Nissan Motor Co Ltd (Japan), Geomega Resources (Canada), and Shenghe Resources Holdings Co., Ltd (China) among others.

Recent Developments:

July 2023: Solvay announced the expansion of its rare earth recycling facility in France, increasing its annual recycling capacity by 50%.

August 2023: American Rare Earths announced the completion of a feasibility study for its rare earth recycling project in the US, paving the way for its development.

September 2023: The European Union published a new strategy for securing the supply of critical raw materials, including rare earths, emphasizing the importance of recycling.

October 2023: A new research project funded by the US Department of Energy was launched to develop innovative technologies for recycling rare earths from permanent magnets.