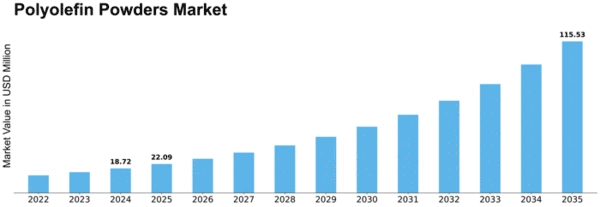

Polyolefin Powders Size

Polyolefin Powders Market Growth Projections and Opportunities

The polyolefin powders market is influenced by several market factors that shape its dynamics and growth trajectory. One of the primary drivers is the increasing demand for polyolefin powders across various industries such as packaging, automotive, construction, and healthcare. These powders offer a range of desirable properties including high strength, chemical resistance, and thermal stability, making them indispensable in numerous applications.

Polyolefin powders, also called fluff or flake, offer high bulk density, narrow particle size distribution, and good powder flowability.

Another significant market factor is the expanding packaging industry, driven by the rising demand for convenient and sustainable packaging solutions. Polyolefin powders are favored for their ability to enhance the mechanical and barrier properties of packaging materials, thereby extending the shelf life of products and reducing food waste. With consumers becoming increasingly environmentally conscious, there is a growing preference for eco-friendly packaging options, further fueling the demand for polyolefin powders.

Moreover, the automotive sector plays a crucial role in driving the demand for polyolefin powders. These powders are utilized in various automotive components such as bumpers, interior trim, and under-the-hood applications due to their lightweight nature and excellent impact resistance. With the automotive industry undergoing a paradigm shift towards electric vehicles and lightweighting initiatives to improve fuel efficiency, the demand for polyolefin powders is expected to witness steady growth.

Furthermore, infrastructural developments and construction activities contribute significantly to the demand for polyolefin powders. These powders find applications in pipes, fittings, insulation materials, and geomembranes used in construction projects. The rapid urbanization and industrialization in emerging economies are driving the demand for advanced construction materials, thereby boosting the market for polyolefin powders.

In addition to end-user industries, market factors such as technological advancements and innovations play a pivotal role in shaping the polyolefin powders market. Manufacturers are constantly investing in research and development activities to enhance the performance characteristics of polyolefin powders, such as improved heat resistance, UV stability, and processing efficiency. These innovations not only cater to existing applications but also open up new avenues for the utilization of polyolefin powders in niche markets.

Moreover, regulatory initiatives and environmental concerns are influencing the market dynamics of polyolefin powders. Stringent regulations regarding the use of certain chemicals and materials in various industries are driving the demand for safer and more sustainable alternatives, thereby favoring the adoption of polyolefin powders. Additionally, increasing awareness about plastic pollution and the need for recyclable materials are prompting manufacturers to develop recyclable and biodegradable polyolefin powders, aligning with the growing trend towards circular economy principles.

Furthermore, the competitive landscape of the polyolefin powders market is characterized by the presence of key players striving to gain a competitive edge through strategies such as mergers and acquisitions, product diversification, and geographical expansion. This intensifying competition is driving manufacturers to focus on quality control, cost optimization, and supply chain efficiency to meet the evolving demands of customers and maintain their market position.

Leave a Comment