Polymeric Plasticizer Size

Polymeric Plasticizer Market Growth Projections and Opportunities

Several market aspects impact the size of the developing market. These market drivers include; increase in demand for flexible and durable plastic products across many industrial sectors. Polymeric plasticizers are commonly used to make plastics more pliant and plastic therefore making them appropriate for applications such as automotive engineering, construction and packaging industry. The increase in demand for polymeric plasticizers is mainly driven by expansion of automobile sector as well as a boom in construction activities.

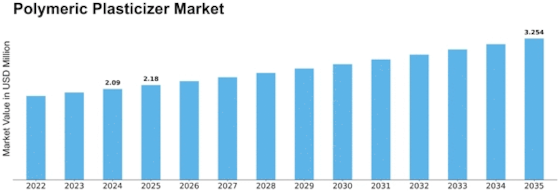

Polymeric Plasticizer Market was worth USD 1.93 million at 2020 having CAGR of 4.10% during forecast period (2022-2030).

Furthermore, environmental legislations are affecting patterns within the market due to shift towards environmental friendly options. One may be aware of ecological effects of traditional plasticizers like phthalates hence prefers biobased or non-toxic ones made from polymers instead. Such changes have been spurred by both legal enforcement as well as consumer consciousness thus prompting manufacturers to invest heavily in sustainable alternatives’ researches and development.

Similarly, the international economic status has a significant influence on the development of polymeric plasticizer market…\Economic growth and industrialization can lead to higher production and use of plastics which will raise the need for polymeric plasticizers.\However, any economic recession can cause underdevelopment or negative impacts on this area.

Market changes depend heavily on technological breakthroughs together with improvements made in polymer based plastics.…These types of products are being enhanced through ongoing R&D aimed at improving their performance and cost-effectiveness. Innovations in manufacturing methods combined with developments that address specific end-user requirements characterize competition among firms involved.

Factors like competition should not be neglected when it comes to polymeric plasticizer business.It means various multinational corporations became noticeable players within tis branch. For example, such enterprises usually make strategic decisions e.g., joint ventures, takeovers and amalgamations aiming either at enlarging their share of polymeric plasticizer market or strengthening their product portfolios.In addition, pricing strategies, supply chain management and distribution networks used by key players also affect the dynamics of this industry.

Concerning polymeric plasticizer market; it is shaped by geographical factors too. Availability of raw materials, regional economic conditions as well as dispersion of manufacturing plants has an effect on the production and consumption patterns of these polymers. Moreover, regulatory variations among regions have a direct impact on market landscape thus requiring manufacturers to consider local compliance with environmental regulations plus regional standards.

Leave a Comment