- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

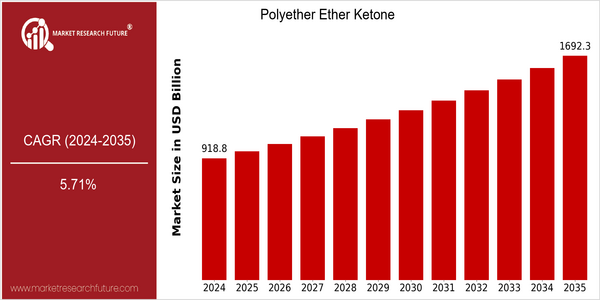

| Year | Value |

|---|---|

| 2024 | USD 918.77 Billion |

| 2035 | USD 1692.32 Billion |

| CAGR (2025-2035) | 5.71 % |

Note – Market size depicts the revenue generated over the financial year

The Polyether-Ether-Ketone (PEEK) market is set for substantial growth, with a current value of $ 918.77 million in 2024, which is expected to grow to $ 1692.32 million by 2035. The CAGR of 5.71% for this period indicates a steady growth. High-performance thermoplastics are in great demand in various industries such as aerospace, automotive and medical, which is a key driver for the market. PEEK is a versatile material with excellent properties such as chemical resistance and mechanical strength, which is favored in the industry. Further technological advancements and improvements in production processes will continue to drive the PEEK market. Companies are investing in research and development to improve the properties of the material and reduce production costs, which will make it available for a wider range of applications. The leading market players such as Victrex plc, Solvay SA and Evonik Industries AG are constantly strengthening their market position through strategic collaborations and product launches. For example, Victrex has recently launched new grades of PEEK tailored to the needs of the market. Strategic alliances between these companies and the increasing use of PEEK in emerging markets will lead to the expansion of the market.

Regional Market Size

Regional Deep Dive

The polyetheretherketone (PEEK) market is characterized by strong growth and widespread applications in the aerospace, automobile and medical industries. Each region has its own trends and is influenced by technological progress, regulations and economic conditions. The increasing demand for high-performance materials that can withstand extreme temperatures drives the innovation and investment in PEEK production and its applications, making it an indispensable material for modern industrial and production processes.

Europe

- Europe is at the forefront of PEEK innovation, with significant investments from companies like Victrex and Solvay in developing new grades of PEEK that cater to the medical and electronics sectors.

- The European Union's stringent regulations on material safety and environmental impact are driving the demand for sustainable and high-performance materials like PEEK, prompting manufacturers to adopt greener production processes.

Asia Pacific

- The Asia-Pacific region is experiencing rapid industrialization, particularly in countries like China and India, which is increasing the demand for PEEK in various applications, including electronics and consumer goods.

- Government initiatives in China aimed at boosting the aerospace and automotive industries are leading to increased investments in PEEK production facilities, with companies like Jiangsu Shuangxing and Shanghai Aoneng expanding their capabilities.

Latin America

- Latin America is seeing a rise in the use of PEEK in the medical sector, particularly in Brazil, where local manufacturers are developing PEEK-based implants and devices to meet increasing healthcare demands.

- The region's economic growth is prompting investments in infrastructure and transportation, leading to a higher demand for PEEK in construction and automotive applications, with local companies beginning to explore its benefits.

North America

- The aerospace sector in North America is witnessing a surge in the adoption of PEEK due to its lightweight and high-temperature resistance properties, with companies like Boeing and Lockheed Martin investing in advanced materials research.

- The increased demand for fuel-efficiency in automobiles is causing manufacturers to look for alternatives to conventional materials. The result is that automobile manufacturers are collaborating with the suppliers of materials.

Middle East And Africa

- In the Middle East, the oil and gas sector is increasingly utilizing PEEK for its chemical resistance and durability, with companies like Saudi Aramco exploring advanced materials for pipeline applications.

- The growing focus on renewable energy projects in Africa is creating new opportunities for PEEK applications in wind and solar energy technologies, as companies seek materials that can withstand harsh environmental conditions.

Did You Know?

“PEEK is one of the few thermoplastics that can withstand continuous use at temperatures up to 260°C (500°F), making it ideal for high-performance applications.” — Victrex

Segmental Market Size

Polyetheretherketone (PEEK) is currently experiencing stable growth, driven by its unique combination of high heat resistance, chemical resistance and strength. The need for lightweight materials in the aircraft and automobile industries, the trend towards using high-performance polymers in medical devices, and the stricter requirements of the medical device industry are driving the demand for PEEK. Companies like Victrex and Solvay are at the forefront of the development of PEEK for the most demanding applications, especially in the aeronautical industry, where weight reduction is critical to fuel efficiency. The use of PEEK is now at a more mature stage, with the industry concentrating on the aircraft, automobile and medical device industries. PEEK is particularly well suited to dental implants and surgical instruments, where it is used because of its biocompatibility and long service life. PEEK is also benefiting from trends towards a more sustainable approach to production and the drive towards greater energy efficiency in manufacturing. PEEK is undergoing a transformation, with new processing and forming methods, such as 3D printing and rheology, enabling it to find new applications and expand its market.

Future Outlook

From 2024 to 2035, the PEEK market will be able to increase from 918.77 million to 1,692.32 million, a strong compound annual growth rate (CAGR) of 5.71%. The increase in PEEK's application in high-tech industries such as aviation, automobiles, and medical equipment is mainly due to its superior thermal stability, chemical resistance, and mechanical properties. PEEK will continue to gain market share in these industries, reaching up to 30% by 2035. However, the main reason for the rapid development of PEEK is the continuous improvement of its technology, especially the rapid development of injection molding and 3D printing. The use of PEEK is also expected to be favored by the government's policy of reducing the carbon footprint of new materials and promoting the development of the circular economy. The integration of PEEK into the components of electric vehicles and the increased demand for medical applications for biocompatibility will also play a key role in the future market. In short, the PEEK market will be able to experience a great change, and the continuous development of high-tech industries will be the main driving force.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Growth Rate | 6.9% (2021-2027) |

Polyether Ether Ketone Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.