Top Industry Leaders in the Polycaprolactone Polyol Market

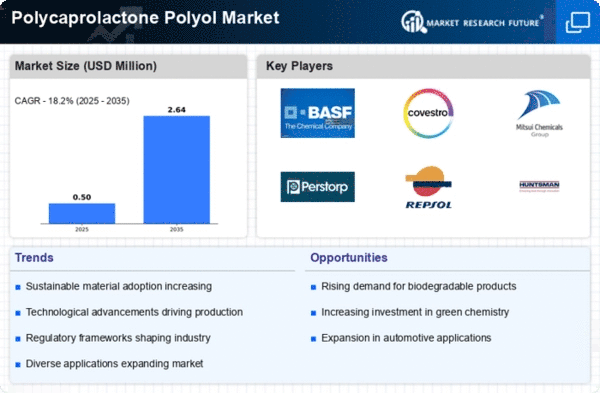

The polycaprolactone polyol (PCL) market is a dynamic space, witnessing a surge in demand due to its diverse applications, primarily in polyurethane (PU) foams, adhesives, and coatings. This burgeoning market attracts a range of players, each vying for a larger slice of the pie.

Strategies Adopted by Key Players:

-

Product Diversification: Leading players like Covestro, BASF, and Dow Chemical are expanding their portfolios by offering PCLs with varying molecular weights, functionalities, and hydroxyl numbers, catering to specific application needs. -

Technological Innovation: Companies like Evonik and Huntsman are investing in research and development to improve PCL properties like biodegradability, flame retardancy, and thermal stability, enhancing their appeal in sustainability-focused sectors. -

Vertical Integration: Some players like Perstorp are integrating upstream with caprolactone production, securing supply chain control and cost advantages. -

Strategic Partnerships and Acquisitions: Collaborations and acquisitions are on the rise, with companies like Mitsui Chemicals acquiring Zhejiang Sanmu Polyurethane to strengthen their regional presence. -

Sustainability Initiatives: Addressing environmental concerns, many players are introducing bio-based PCLs and adopting sustainable manufacturing practices, attracting eco-conscious consumers.

Factors Influencing Market Share:

-

Product Quality and Consistency: Consistent supply of high-quality PCLs with desired properties is crucial for gaining customer trust and market share. -

Technical Expertise and Application Support: Providing extensive technical support and application development assistance to customers empowers them to leverage PCL's full potential. -

Geographical Presence and Distribution Network: A strong global presence and robust distribution network ensure efficient product delivery and market reach. -

Pricing Strategies and Cost Competitiveness: Competitive pricing and cost-effective production methods are key to attracting price-sensitive customers. -

Brand Reputation and Customer Relationships: Building strong brand recognition and fostering long-term customer relationships through reliable service and product innovation are vital for market leadership.

List of Key Players Covered in the Report

- Perstrop Holdings A.B.

- BASF SE

- Daicel Corporation

- Sigma Aldrich

- Shenzhen Esun Industrial Co., Ltd

- Gantrade Corporation, Huntsman International LLC (U.S)

Industry News

Feb 2022 - Ingevity is preparing to start producing caprolactone polyols at its DeRidder, Louisiana factory. It plans to enhance the global production capacity for the polyols sold under the Capa brand by 40%. Construction is anticipated to commence by summer, with operations beginning in the first quarter of 2022. Monomer storage capacity will be included in the project, which will help speed bulk shipments to customers in the United States. A ring-opening polymerization reaction is used in the production process. This enables the monomer to be derivatized into various polyols and thermoplastics with added value. Another investment in Capa, a Warrington, United Kingdom-based innovation center, should be operating by the end of the year. It will contain application development equipment and testing capabilities. The DeRidder factory modifications will better position Ingevity to meet rising global demand for Capa technologies while also improving the supply chain, reducing lead times, and improving overall service for clients worldwide.

January 2021- Aqua Metals, Inc, a leading player who specializes in lead recycling with its AquaRefining technology, has announced that it has partnered with BASF SE, a German player, to supply electrolytes, cooperate commercially and explore technical improvements to enhance AquaRefining performance.

January 2021- Air Liquide and BASF SE has signed a contract in South Korea;s Yeosu National Industrial Complex to extend the term of their existing agreements. The first contract between the two players was signed 20 years ago. Since then, Air Liquide has expanded its industrial reach in the Yeosu basin.

The Sulzer company, in November 2023, introduced the CAPSUL technology that is projected to revolutionize the production of polycaprolactone (PCL). One of its applications is as a biodegradable polyester used for many purposes, such as packaging, textiles, agriculture and horticulture. This latest CAPSUL technology improves efficiency, making it possible for producing competitive, high-quality PCL grades. This adds to Sulzer’s range of renewable and circular plastics technologies, including polylactic acid (PLA) process technology.