Market Share

Pneumatic Components Market Share Analysis

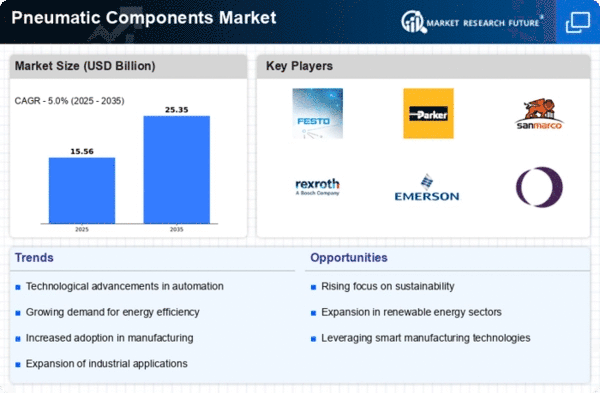

The surge in investments in industrial automation is poised to significantly drive the demand for pneumatic components, given their integral role in powering devices used in this sector through compressed air. This momentum aligns with the continuous growth of Industrial Internet of Things (IIoT) and the ever-expanding realm of predictive analytics, showcasing a trend that shows no signs of slowing down. Pneumatic devices and controls are pivotal players in this movement, continually advancing to enhance and smarten automation and control processes. The versatility of pneumatic systems is increasingly evident in various industrial applications, and the integration of new sensing and data communication technologies is making pneumatics more intelligent and easily adaptable to the Industrial Internet of Things. Looking ahead, the evolution of smart sensing technologies is expected to play a crucial role in shaping the future of pneumatics. The incorporation of affordable sensing and information processing technology is becoming a standard feature in various fluid power equipment components, spanning from connectors, tubing, and hoses to pneumatic cylinders, actuators, and filters. In parallel, remarkable strides have been made in the field of robotics within industrial automation. Notably, the impact of robotics-driven factory automation and artificial intelligence is exemplified by Amazon's ability to deliver around five billion items in just two days in 2018. Pneumatic components, particularly pneumatic actuators, contribute significantly to these advancements in industrial automation. The utilization of wireless sensors and valve controls in advanced pneumatic actuators not only enhances their performance but also enables predictive maintenance capabilities. A noteworthy recent development in industrial automation is the introduction of a pneumatically powered production cell designed for low-cost automation applications. This innovative cell has the potential to elevate production efficiency and output quality at an economical cost. As a result, over the research period, the growing integration of pneumatic components in industrial automation is anticipated to create promising opportunities for companies operating in the global pneumatic components market. the increasing focus on industrial automation, coupled with advancements in IIoT and predictive analytics, positions pneumatic components as vital contributors to the ongoing transformation. The adaptability of pneumatic systems, combined with the evolution of smart sensing technologies and their integral role in robotics, reinforces the significance of pneumatic components in shaping the future of industrial automation. The potential for growth and opportunities in the global pneumatic components market is underscored by these developments, as they continue to play a crucial role in enhancing efficiency, reliability, and cost-effectiveness in industrial processes.

Leave a Comment