Plating On Plastics Size

Plating on Plastics Market Growth Projections and Opportunities

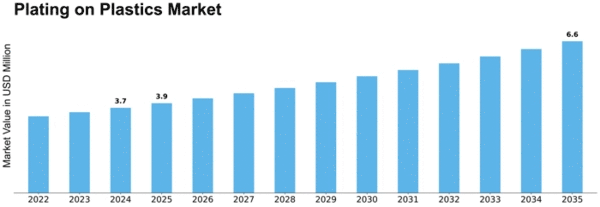

Many market factors affect the growth and direction of the Plating on Plastics (POP) industry. The growing need for lightweight and attractive components in enterprises is a major factor. Plating on plastics, which applies metal coatings to plastic surfaces, addresses this interest by combining the benefits of metals with plastics. This has boosted POP usage in the auto industry, as manufacturers aim to improve the look and performance of inside and outside components while maintaining lightweight features for eco-friendliness. Plated on plastics market value is expected to reach $654.79 Million by 2030 with a 4.8% CAGR.

Also, the consumer electronics industry boosts the POP market. The growing use of plastic in electronics and the desire for sleek, attractive devices fuel the need for plated plastic components. POP offers plastic electronics parts a metallic finish and improves their strength and conductivity. This application affects cell phones, desktops, and wearables, changing the market.

Continuous plating innovation and improvement is another important market aspect. The market is shaped by plating process innovations such environmentally friendly and maintainable plating solutions. Making procedures that reduce environmental impact, comply with strict standards, and follow reasonable norms is becoming more important. These innovations meet end-user needs and boost the POP industry.

The POP market is also affected by the geological distribution of assembly and end-use businesses. Plated plastic components are popular in regions with strong assembly and consumer buying power. As firms adopt cutting-edge technologies and materials, emerging nations with growing assembly areas are rewarding POP marketplaces. Regional preferences, legislation, and the economy also affect market components.

The car industry, a major POP user, is sensitive to global economic situations. Plated plastic component demand is directly affected by vehicle market fluctuations caused by economic downturns or consumer preferences. The POP market relies on repeated patterns influenced by the economy.

In the POP market, administrative considerations and industry rules are important. As environmental and health standards tighten, companies must ensure their plating methods comply. Administrative requirements boost POP market acceptance and provide assembly process safety and supportability.

Leave a Comment