- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

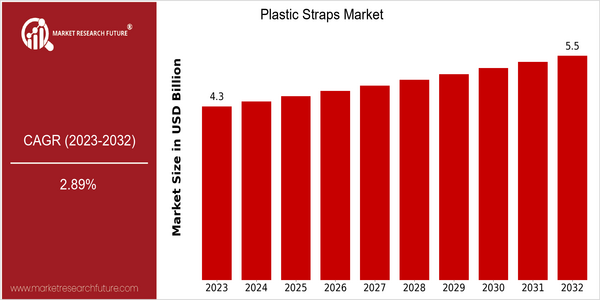

| Year | Value |

|---|---|

| 2023 | USD 4.26 Billion |

| 2032 | USD 5.5 Billion |

| CAGR (2024-2032) | 2.89 % |

Note – Market size depicts the revenue generated over the financial year

The world market for plastic straps is expected to reach $ 4.26 billion in 2023 and $ 5.41 billion by 2032, at a CAGR of 3.06% between 2024 and 2032. The continuous growth of this market shows the enduring demand for plastic straps in many industries, which are mainly due to their versatility and cost-effectiveness in the packaging and fastening of products. As the logistics and supply chain become more important for enterprises, the demand for plastic straps will also increase, thus driving the growth of the market. The main driving force of this market is the development of new materials and production methods, which have a greater effect on the stability and performance of plastic straps. The development of new materials such as biodegradable materials and the automation of packaging processes are also developing in line with the trend of the times. The major players in the industry, such as Signode Industrial Group, Polychem and Samuel Strapping, have also taken strategic measures, such as establishing a joint venture and launching new products, to improve their market share and meet the needs of customers. These efforts not only improve the competition of the industry, but also promote the development of the whole market.

Regional Market Size

Regional Deep Dive

Throughout the world, the market for plastic straps is characterized by different dynamics, primarily due to differences in industrial demands, regulatory frameworks and economic conditions. In North America, the market is supported by a strong manufacturing industry and the increasing adoption of sustainable packaging solutions. Europe is experiencing a shift towards eco-friendly materials, while Asia-Pacific is experiencing rapid urbanization and industrialization, which is accompanied by increased demand for plastic straps in logistics and packaging. The Middle East and Africa are slowly developing their manufacturing industries, while in Latin America the focus is on improving the efficiency of supply chains, which is having a significant impact on the market.

Europe

- The European Union's stringent regulations on plastic usage are driving innovation in the development of biodegradable plastic straps, with companies like Signode and Strapex leading the charge.

- Sustainability initiatives are gaining traction, with many companies adopting circular economy principles, which is reshaping the production and consumption patterns of plastic straps in the region.

Asia Pacific

- Rapid industrialization in countries like China and India is significantly increasing the demand for plastic straps in various sectors, including construction and logistics.

- Innovations in manufacturing processes, such as the use of advanced polymers, are being adopted by key players like Teufelberger and Polychem, enhancing the performance and durability of plastic straps.

Latin America

- The growth of the agricultural sector in Brazil and Argentina is leading to increased usage of plastic straps for bundling and securing products, enhancing supply chain efficiency.

- Local manufacturers are focusing on cost-effective production methods to compete with imported products, which is influencing pricing strategies and market dynamics.

North America

- The rise of e-commerce has led to increased demand for efficient packaging solutions, with companies like Amazon and Walmart investing in advanced packaging technologies that include plastic straps.

- Regulatory changes in California aimed at reducing plastic waste are prompting manufacturers to innovate with biodegradable and recyclable plastic strap options, influencing market dynamics.

Middle East And Africa

- The region is witnessing an increase in infrastructure projects, particularly in the UAE and Saudi Arabia, which is driving demand for durable plastic straps in construction and packaging.

- Government initiatives aimed at boosting local manufacturing capabilities are encouraging investments in the production of plastic straps, with companies like Al-Futtaim and Al-Hokair Group expanding their operations.

Did You Know?

“Plastic straps are not only used for packaging but also play a crucial role in securing goods during transportation, with some straps capable of holding up to 1,000 pounds.” — International Journal of Packaging Technology and Science

Segmental Market Size

The market for plastic straps is experiencing a steady growth, mainly driven by the growing demand from the packaging, logistics, and construction industries. There is an increasing need for secure packaging and an increasing need for efficient supply chains. The regulation of the packaging materials also influences the manufacturers to adopt the plastic straps that meet the requirements. The use of plastic straps is now in a mature stage, with companies such as Signode Industrial Group and Polychem leading the innovation and application of plastic straps. The main applications are to secure the goods for transportation, to bundle the goods in the retail industry, and to strengthen the pallets in the warehouses. The notable trends in the future are the shift towards green materials and the development of the strapping equipment, such as the automatic strapping machine. The biodegradable straps are also popular in the market, and the trend of using biodegradable straps is driven by the sustainable development.

Future Outlook

The market for plastic straps will rise steadily from 2023 to 2032, with an increase from US$4.26 billion to US$5.5 billion, and a CAGR of 2.89% from 2023 to 2032. The growth is mainly driven by the increasing demand for packaging in various industries, such as logistics, construction and consumer goods. Also, with the increase in the importance of the environment, the use of biodegradable and degradable straps will increase, and the market will continue to grow. By 2032, the market penetration rate of the green strap is expected to reach about 30%, which is in line with the trend of sustainable development and the demand of green products. The development of high-strength, light-weight materials and the automation of strapping machines will help to improve the efficiency and quality of plastic straps in the packaging industry. The trend of the market is still upward. The trend of integrating smart technology into packaging solutions will also provide opportunities for market growth and differentiation. The market for plastic straps is expected to change a lot in the future, and the driving force will be the demand of the public, the development of science and technology, and the impact of the law.

Plastic Straps Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.