Market Trends

Key Emerging Trends in the Piezoelectric Ceramics Market

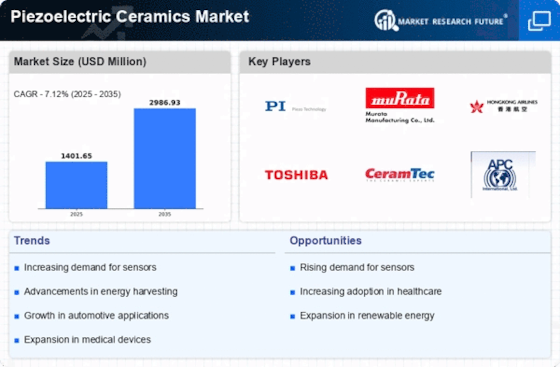

The Piezoelectric Ceramics Market is witnessing several key trends that are shaping its landscape. One prominent trend is the increasing adoption of piezoelectric ceramics in the automotive sector. As the automotive industry undergoes a transformation toward electric and autonomous vehicles, piezoelectric materials find applications in various components, including sensors for vehicle safety, fuel injection systems, and vibration monitoring. The demand for piezoelectric ceramics in the automotive sector is expected to grow as the industry continues to prioritize innovations in energy efficiency and driver-assistance technologies.

Another notable trend is the rising use of piezoelectric ceramics in healthcare applications. The healthcare sector is increasingly incorporating piezoelectric materials in medical devices such as ultrasound transducers, diagnostic equipment, and implantable devices. The precision and reliability offered by piezoelectric ceramics make them well-suited for medical applications, driving the market's growth in the healthcare sector. As medical technology advances, the demand for high-performance piezoelectric materials is expected to increase further.

Energy harvesting represents a significant trend in the piezoelectric ceramics market. With a growing emphasis on renewable energy sources, piezoelectric materials are being employed to convert mechanical vibrations from various sources, such as machinery and infrastructure, into electrical energy. This trend aligns with global efforts to explore sustainable energy solutions, and it positions piezoelectric ceramics as a key player in the field of energy harvesting for self-powered devices and sensor networks.

Smart infrastructure development is also contributing to market trends. Piezoelectric ceramics play a crucial role in structural health monitoring systems, where they are utilized to detect and measure vibrations, stress, and strain in buildings, bridges, and other infrastructure. The integration of smart sensors using piezoelectric materials enhances the ability to monitor and assess the condition of structures in real-time, facilitating predictive maintenance and ensuring the longevity of infrastructure components.

The Internet of Things (IoT) is driving increased demand for piezoelectric ceramics. As more devices become interconnected, the need for efficient sensors and actuators grows. Piezoelectric materials provide a reliable and responsive solution for sensors in IoT applications, contributing to the seamless functioning of interconnected devices. The proliferation of IoT across industries, from industrial automation to consumer electronics, is expected to fuel the demand for piezoelectric ceramics.

Advancements in manufacturing technologies are influencing market trends as well. Companies are investing in research and development to enhance the production processes of piezoelectric ceramics, resulting in improved efficiency and cost-effectiveness. These advancements contribute to the expansion of the market by making piezoelectric materials more accessible to a wider range of industries.

Customization and specialization are emerging trends in response to the diverse application requirements of different industries. Companies are focusing on developing piezoelectric ceramics tailored to specific applications, such as high-temperature environments, underwater applications, or extreme operating conditions. This trend allows companies to cater to the unique needs of various sectors, fostering customer satisfaction and loyalty.

Leave a Comment