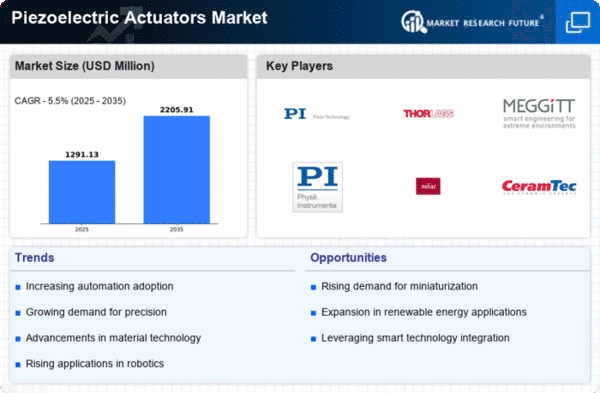

Piezoelectric Actuators Size

Piezoelectric Actuators Market Growth Projections and Opportunities

The Packaging Assembly Equipment Market is influenced by a myriad of market factors that collectively shape its dynamics and growth trajectory. One of the key drivers propelling the market is the escalating demand for efficient and streamlined packaging processes across diverse industries. As companies increasingly focus on optimizing their packaging operations to enhance productivity and reduce costs, the need for advanced packaging assembly equipment becomes paramount. This surge in demand is further fueled by the growing global population and subsequent rise in consumption, driving industries to adopt automation and robotics in packaging to meet escalating production demands.

Moreover, the evolving regulatory landscape plays a pivotal role in shaping the packaging assembly equipment market. Stringent regulations regarding packaging standards and environmental sustainability have compelled manufacturers to invest in equipment that not only ensures compliance but also minimizes environmental impact. This has led to a growing preference for eco-friendly and recyclable packaging materials, prompting the integration of advanced assembly equipment capable of handling such materials efficiently. As sustainability continues to gain prominence, the market is witnessing a shift towards greener technologies and practices.

Technological advancements also exert a profound influence on the packaging assembly equipment market. The integration of Industry 4.0 technologies, such as the Internet of Things (IoT) and artificial intelligence, is revolutionizing packaging processes. Smart packaging assembly equipment equipped with sensors and connectivity features enables real-time monitoring, predictive maintenance, and data-driven decision-making. This not only enhances operational efficiency but also contributes to minimizing downtime, a crucial factor in industries where continuous production is imperative.

Furthermore, the competitive landscape and market consolidation significantly impact the packaging assembly equipment sector. Companies are engaging in strategic collaborations, mergers, and acquisitions to expand their product portfolios and market presence. This trend is fostering innovation as market players strive to stay ahead in the fiercely competitive environment. The resultant influx of new and improved packaging assembly equipment options gives end-users a broader spectrum of choices, further propelling market growth.

Global economic conditions and geopolitical factors also play a role in shaping the packaging assembly equipment market. Fluctuations in currency exchange rates, trade policies, and geopolitical tensions can impact the cost of raw materials, manufacturing, and distribution. These factors, in turn, influence the pricing strategies of market players and can pose challenges or opportunities depending on the prevailing economic conditions.

Lastly, the COVID-19 pandemic has underscored the importance of resilient and adaptive supply chains, prompting companies to reevaluate their packaging strategies. The need for contactless and hygienic packaging solutions has intensified, driving the adoption of advanced assembly equipment capable of meeting these evolving requirements. The pandemic has accelerated the pace of digital transformation in the packaging industry, with a focus on automation, remote monitoring, and agility in response to market dynamics.

Leave a Comment