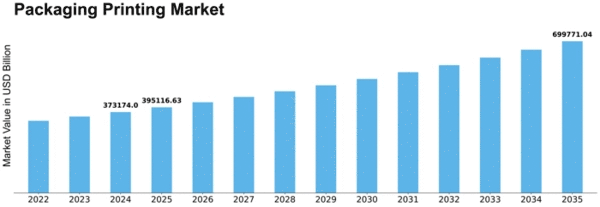

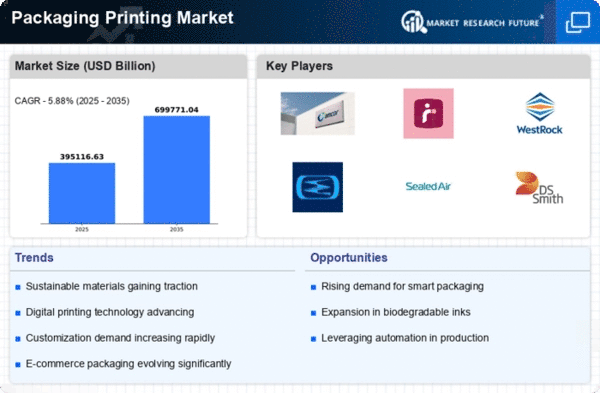

Packaging Printing Size

Packaging Printing Market Growth Projections and Opportunities

The packaging printing market is influenced by various factors that shape its dynamics and determine its performance. Packaging printing plays a crucial role in enhancing the visual appeal, brand identity, and product information of packaged goods across industries such as food and beverages, pharmaceuticals, cosmetics, and consumer goods. One of the primary market factors impacting the global packaging printing market is the increasing demand for packaged products. As consumer preferences evolve and competition in the market intensifies, there is a growing emphasis on packaging design and branding to attract consumers and differentiate products on retail shelves. Packaging printing offers various solutions, including vibrant colors, intricate designs, and innovative finishes, driving its adoption in the packaging industry and contributing to market growth.

Packaging printing technology is utilized for enclosing, protecting the products for distribution, storage, sales, and usage. Though the primary reason for the packaging s to store the products, the packaging printing technology acts as product and brand promotion and aids in creating a strong relationship with the consumers. With the increasing innovations in the field and novel methods in presenting the product to the consumer, Packaging Printing Market has been witnessing tremendous growth in the past few decades

Moreover, technological advancements and innovations significantly influence the global packaging printing market. Manufacturers are constantly innovating to develop printing technologies with improved performance, efficiency, and versatility to meet the evolving needs of different industries and applications. For example, advancements in digital printing technologies, such as inkjet and electrophotography, offer high-quality printing with short turnaround times and cost-effectiveness, meeting the demands of fast-paced industries such as food and beverages. Additionally, innovations in printing inks, substrates, and finishing techniques enable manufacturers to achieve various effects, such as metallic finishes, embossing, and holographic effects, enhancing the visual appeal of packaging.

Furthermore, regulatory factors play a crucial role in shaping the global packaging printing market. Regulations and standards related to product safety, labeling, and environmental sustainability drive the adoption of packaging printing solutions that comply with regulatory requirements. For example, regulations governing food contact materials, such as the Food Contact Materials Regulation (EC) No 1935/2004 in the European Union, mandate the use of printing inks that are safe for food contact. Similarly, regulations related to product labeling, such as the Nutrition Labeling and Education Act (NLEA) in the United States, require accurate and informative printing on packaged products. Compliance with regulatory requirements is essential for packaging printing manufacturers to access key markets and maintain customer trust.

Market dynamics such as supply chain considerations and technological advancements also impact the global packaging printing market. The packaging printing supply chain involves multiple stages, including the sourcing of raw materials, manufacturing of printing inks and substrates, printing of packaging materials, and distribution to end-users. Disruptions at any stage of the supply chain, such as raw material shortages, transportation bottlenecks, or regulatory challenges, can affect the availability and pricing of packaging printing solutions. Additionally, advancements in printing technologies, such as hybrid printing systems that combine digital and flexographic printing, enable manufacturers to offer customized and cost-effective solutions, driving adoption in the packaging industry.

Moreover, market factors such as globalization and trade policies influence the global packaging printing market. As packaging printing manufacturers expand their operations to new markets and regions, there is a growing demand for printing solutions that comply with local regulatory requirements and cultural preferences. Additionally, trade policies, tariffs, and international agreements related to printing materials and technologies can impact the competitiveness of packaging printing manufacturers in global markets, affecting market dynamics and pricing. Understanding these market factors and adapting manufacturing and distribution strategies accordingly is essential for packaging printing manufacturers to remain competitive in the dynamic and evolving global market.

Leave a Comment