Market Trends

Key Emerging Trends in the Organic Polysulfide Market

The dynamic chemical and industrial sectors are affecting the Specialty Oxidants market. Demand and uses for specialty oxidants, a varied variety of chemical compounds with high oxidizing capabilities, are changing across sectors. In water treatment, specialized oxidants are becoming more popular. These compounds disinfect and remove pollutants from water sources, addressing water quality and safety concerns. Industry and municipalities are seeking sustainable and effective water treatment solutions, driving demand for specialty oxidants for microbiological control and environmental remediation.

In the polymer and plastic sectors, specialist oxidants are in high demand. Oxidants start reactions, crosslink polymers, and improve material characteristics during polymerization. As demand for advanced polymers with durability, flexibility, and thermal stability rises, specialty oxidants help develop customized polymer formulations for packaging, automotive, and electronics applications.

The Specialty Oxidants market is also seeing formulation developments to fulfill industry needs. Customized oxidants with regulated reactivity, substrate compatibility, and decreased environmental impact are being developed by manufacturers. This trend is driven by the requirement for oxidants that can meet strict safety and environmental criteria while addressing numerous industry concerns.

In the chemical sector, especially specialty oxidants, safety, environmental effect, and sustainability are becoming regulatory priorities. Manufacturers are adjusting formulas to meet emissions, toxicity, and environmental safety laws. These trends reflect the industry's commitment to responsible chemical use and global efforts to reduce chemical manufacturing's environmental impact.

Demand is also growing geographically, especially in emerging economies. Asia-Pacific's growing industrialization and urbanization are boosting demand for specialty oxidants in water treatment, polymer manufacture, and industrial processes. These nations' growing markets provide manufacturers possibilities to develop a significant presence and meet varied sectors' needs.

Technology in the Specialty Oxidants market is improving manufacturing efficiency and reducing environmental impact. Manufacturers are investigating innovative synthesis and oxidation methods, sustainable raw material sources, and high-performance specialized oxidants. The chemical production sector is moving toward green chemistry and sustainable methods.

In conclusion, the Specialty Oxidants market is driven by rising water treatment demand, polymer and plastic demand, oxidant formulation advances, regulatory compliance, geographic expansion, and technological innovations for efficient and sustainable production. As industries prioritize water quality, sophisticated materials, and sustainable chemical solutions, Specialty Oxidants market stakeholders must stay informed to traverse the dynamic landscape and capitalize on growing possibilities in various sectors.

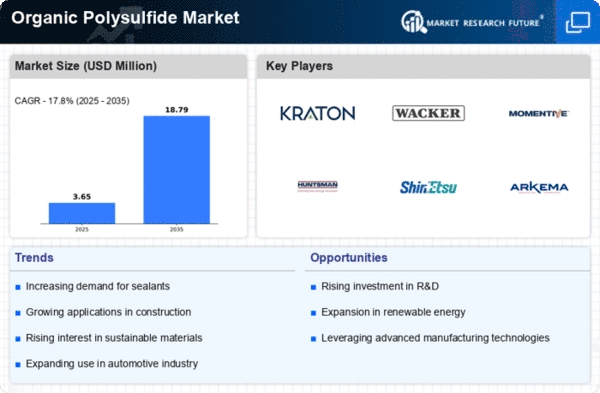

User Create a 600-word paragraph on Organic Polysulfide Market Trends for ChatGPT. Organic Polysulfide market developments reflect the dynamic chemical and building sectors. Organic polysulfides, chemical molecules with sulfur-sulfur linkages, are changing demand and uses throughout industries. In construction and sealant, organic polysulfides are becoming more popular. Due to their chemical resistance and endurance, polysulfide sealants are used in joints, expansion joints, and waterproofing. Organic polysulfides are in demand for their sealing and environmental protection as the construction industry prioritizes high-performance materials for infrastructure projects.

In the automotive and aerospace industries, organic polysulfides are in high demand. Organic polysulfides are used to make fuel-resistant gaskets, seals, and coatings for chemical and extreme-condition applications. Organic polysulfides are becoming more popular for their chemical qualities as these industries prioritize materials that can tolerate harsh environments and work reliably.

Organic Polysulfide formulations are also evolving to fulfill industry needs. Organic polysulfides with increased flexibility, adhesion to diverse substrates, and chemical resistance are being developed by manufacturers. The necessity for versatile polysulfides that can solve industry problems drives this movement.

Safety and environmental effect are becoming regulatory priorities in the chemical sector, particularly organic polysulfides. Manufacturers are adjusting formulas to meet emissions, toxicity, and environmental safety laws. This trend aligns with global initiatives to reduce chemical manufacturing's environmental impact by promoting sustainable methods and responsible chemical use.

Demand is also growing geographically, especially in emerging economies. Organic polysulfides are in demand for construction, automotive, and infrastructure applications due to rising industrialization and urbanization in Asia-Pacific. These nations' growing markets provide manufacturers possibilities to develop a significant presence and meet varied sectors' needs.

The Organic Polysulfide market is undergoing production process developments to improve efficiency and reduce environmental impact. Advanced synthesis, sustainable raw material sourcing, and better organic polysulfides are being investigated by manufacturers. This trend supports industry efforts to promote green chemistry and sustainable chemical manufacture.

Leave a Comment