Top Industry Leaders in the Nylon Fiber Market

Nylon fibers, those ubiquitous threads woven into our lives from carpets to airbags, represent a multi-billion dollar market teeming with competition and innovation. The nylon fibers landscape is a complex tapestry where established players and nimble newcomers vie for dominance. Let's untangle the strategies, factors impacting market share, recent industry news, and the intricate developments shaping this dynamic sphere.

Strategic Masterstrokes in the Nylon Battlefield:

-

Product Diversification: Giants like DuPont and Ascend Performance Materials are pushing boundaries, expanding beyond traditional nylon 6 and 6,6 to cater to niche applications with specialty nylons offering enhanced heat resistance, flame retardancy, or biodegradability. -

Geographical Expansion: Asia-Pacific, fueled by its thriving automotive and textile industries, beckons for expansion. Aquafil's entry into Vietnam exemplifies this trend. -

Vertical Integration: Gaining control over raw materials is a cost-saving and resilience-building mantra. UBE Corporation's investment in adiponitrile production strengthens its supply chain. -

Technological Innovation: Embracing sustainability and circularity is key. INVISTA's ECONYL® nylon, made from recycled fishing nets, showcases this shift. Additionally, advances in recycling technologies are unlocking opportunities for closed-loop nylon production. -

Strategic Partnerships: Joining forces with downstream users in key industries like automotive or apparel can secure long-term demand and market access. Asahi Kasei's collaboration with a leading tire manufacturer exemplifies this strategy.

Unveiling the Threads of Market Share:

-

Production Powerhouses: Established players like BASF and Toray hold significant sway due to their extensive production capacities and global networks. However, regional players like China's Nanhua Group are challenging this dominance with lower production costs and localized expertise. -

Application Diversification: While textiles and carpets remain the major consumers, growth in segments like automotive interiors, filtration systems, and medical textiles offers opportunities for players targeting specific niches. -

Environmental Regulations: Stringent regulations on energy consumption and waste disposal can favor companies with sustainable practices and resource-efficient production processes. -

Raw Material Fluctuations: Fluctuations in the prices of key raw materials like crude oil and adiponitrile can impact production costs and profit margins. -

Consumer Trends: Increasing demand for eco-friendly and durable textiles creates opportunities for sustainable and performance-driven nylons.

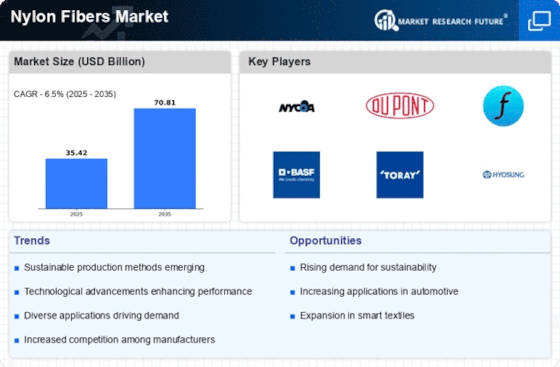

Key Players:

Evonik Industries AG (Germany), BASF SE (Germany), Solvay (Belgium), Radici Partecipazioni SpA (Italy), Shenma Industrial Co., Ltd. (China), Ascend Performance Materials (US), INVISTA (US), Asahi Kasei Corporation (Japan), DuPont de Nemours, Inc. (US), EMS-CHEMIE HOLDING AG (Switzerland), Shakespeare Company, LLC. (US), and LIBOLON (Taiwan).

Recent Developments Weaving the Nylon Landscape:

July 2023: DowDuPont launches a new bio-based nylon fiber made from corn, paving the way for sustainable alternatives in the textile industry.

September 2023: Sumitomo Chemical unveils a novel dyeing process for nylon fibers that reduces water consumption and wastewater generation.

October 2023: Ascend Performance Materials announces a partnership with a start-up developing biodegradable nylon fibers for wipes and disposable hygiene products.

November 2023: Toray expands its production capacity for high-performance nylon fibers used in aircraft interiors, anticipating increased demand from the aerospace industry.