Top Industry Leaders in the Multi Layer Cryogenic Insulation Market

The multi-layer cryogenic insulation market is steadily expanding on the back of rising demand for efficient cryogenic storage and transportation within energy, healthcare, and space exploration industries. This intricate web of players is characterized by established giants jockeying for dominance alongside nimble niche players pushing technological boundaries. Understanding the strategies, factors influencing market share, and recent developments is crucial for anyone navigating this dynamic landscape.

Strategies Shaping the Competition:

- Product Diversification: Leading players like Saint-Gobain and Aspen Cryogenics are extending their portfolio beyond traditional materials like PU/PIR to include high-performance options like evacuated powder insulations (EVPI) and nanogel-based solutions. This caters to diverse application needs and bolsters customer loyalty.

- Geographical Expansion: Established players are setting up production facilities in regions like APAC and the Middle East, capitalizing on the rapid growth in LNG infrastructure and healthcare. This reduces import dependence and fosters closer connections with local customers.

- R&D Focus: Continuous research and development play a vital role in staying ahead of the curve. Companies like BASF and Johns Manville are investing heavily in advanced materials, fire-retardant properties, and lightweight insulations to meet stringent regulations and improve efficiency.

- Acquisitions and Collaborations: Strategic acquisitions and partnerships are becoming increasingly common. For example, Aspen Cryogenics' acquisition of Vacuum Barrier Corporation strengthened its hold on the EVPI segment, while collaborations between Cryoquip and Oxford Instruments foster innovation in medical cryogenic systems.

- Sustainability Push: With rising environmental concerns, eco-friendly solutions are gaining traction. Companies like Owens Corning are developing bio-based and recyclable insulation materials, appealing to environmentally conscious consumers and adhering to stricter regulations.

Factors Influencing Market Share:

- Technological Advancements: New materials and manufacturing processes hold immense potential for disrupting the market. Players offering superior thermal performance, cost-effectiveness, and ease of installation stand to gain significant ground.

- End-User Applications: The diverse needs of industries like LNG, healthcare, and space exploration drive demand for specialized insulation solutions. Players catering to specific niche applications through tailored offerings hold an advantage.

- Regional Growth: The APAC region, particularly China and India, is witnessing a surge in demand due to infrastructure development and growing LNG usage. Companies with a strong regional presence and understanding of local regulations are well-positioned to capitalize on this.

- Price Fluctuations: Raw material price volatility can pose challenges for smaller players. Established companies with diversified supply chains and larger production volumes have a buffer against these fluctuations.

- Regulations and Environmental Concerns: Stringent regulations governing fire safety and environmental impact are shaping the market. Players offering compliant and sustainable solutions hold an edge over competitors struggling to adapt.

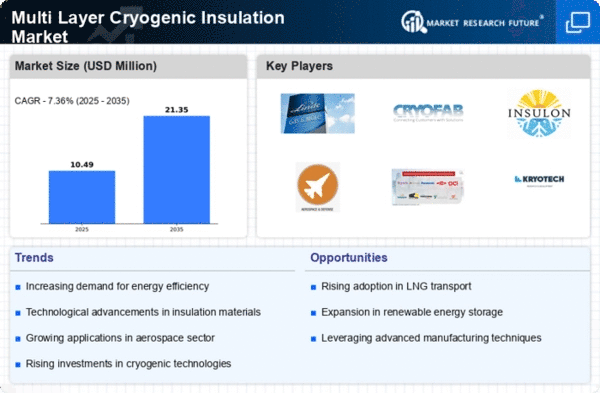

List of Key Players in the Multi-Layer Cryogenic Insulation Market

- Armacell International Holding GmbH (Germany)

- Lydall Inc. (US)

- Cabot Corporation (US)

- Technifab Products (US)

- Dunmore Corporation (US)

- NICHIAS Corporation (Japan)

- Aspen Aerogels (US)

- Owens Corning (US)

- Isolatie Combinatie Beverwijk B.V. (Netherland)

- Abhijit Enterprises (India).

Recent Developments:

September 2023: Aspen Aerogels secures funding from the US Department of Energy to develop next-generation cryogenic insulation for medical applications.

October 2023: Cryogenic Insulation Systems announces a strategic partnership with a leading Chinese LNG player to expand its presence in the Asia-Pacific market.

November 2023: Johns Manville launches an online knowledge center dedicated to MLCI technologies and applications, aiming to educate customers and strengthen brand visibility.

December 2023: BASF and Air Liquide announce a joint research project to develop sustainable and cost-effective MLCI solutions for the food and beverage industry.