- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

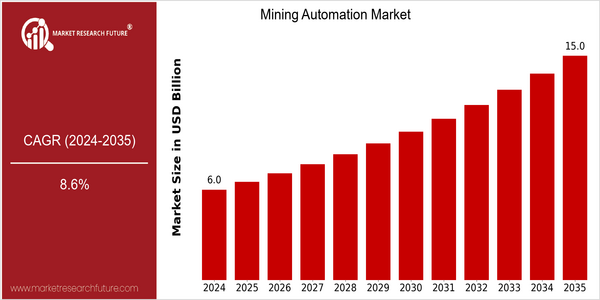

| Year | Value |

|---|---|

| 2024 | USD 6.05 Billion |

| 2035 | USD 15.0 Billion |

| CAGR (2025-2035) | 8.6 % |

Note – Market size depicts the revenue generated over the financial year

The mining automation market is expected to reach a value of $ 6.05 billion by 2024, which is expected to reach $ 15 billion by 2035. This growth is a strong compound annual growth rate (CAGR) of 8.6% from 2025 to 2035. This growth is driven by increasing demand for efficiency, safety and productivity in mining operations. It is also due to technological developments, such as unmanned ground vehicles, advanced robots and artificial intelligence, which are revolutionizing the mining industry. This allows companies to optimize the extraction of resources while reducing the risk to people and the environment. These developments are also due to the fact that the main players in the market, such as Caterpillar, Komatsu and Sandvik, are investing in innovation and strategic collaborations to enhance their product offerings. Caterpillar has developed the most advanced haulage systems, while Sandvik has launched advanced automation solutions with real-time data analysis. The main players in the market are also developing their own automation solutions, such as the Mining and Rock Mechanics (MARM) program, which is the first automation program for the mining industry. These developments not only show the competition, but also show the commitment of the industry to the automation of mining operations, which increases efficiency and sustainability.

Regional Market Size

Regional Deep Dive

The Mining Automation Market is experiencing a significant growth in various regions, which is driven by technological developments, the rising demand for efficiency, and the rising concern for safety and environment. North America is the largest market for mining automation. This market is characterized by the presence of the leading technology suppliers and an enabling regulatory environment. Europe is undergoing a shift towards digitalization and smart mining solutions, whereas the Asia-Pacific region is rapidly adopting automation for improving productivity in its vast mining operations. The Middle East and Africa region is focusing on the development of mining and automation and the need to increase productivity. The Latin American region is focusing on automation to overcome labor shortages and improve safety.

Europe

- The European Union's Green Deal is influencing mining operations to adopt more sustainable practices, leading to increased investment in automation technologies that reduce carbon footprints.

- Companies such as Sandvik and Epiroc are innovating in the field of remote-controlled and automated drilling systems, which are becoming essential for enhancing operational efficiency and safety in European mines.

Asia Pacific

- China is rapidly advancing its mining automation capabilities, with state-owned enterprises investing heavily in autonomous haulage systems and smart mining technologies to boost productivity.

- Australia is seeing a surge in the use of drones and IoT devices in mining operations, with companies like BHP and Rio Tinto implementing these technologies to optimize resource extraction and improve safety.

Latin America

- Countries like Chile and Brazil are adopting automation technologies to address labor shortages and improve safety standards in their mining sectors, with significant investments from companies like Vale and Codelco.

- The region is also witnessing a rise in partnerships between local mining companies and technology providers to develop customized automation solutions that cater to specific operational challenges.

North America

- The integration of AI and machine learning in mining operations is gaining traction, with companies like Caterpillar and Komatsu leading the charge in developing autonomous vehicles and predictive maintenance solutions.

- Regulatory changes in the U.S. and Canada are promoting the adoption of automation technologies, particularly in response to safety concerns and environmental regulations, which are pushing mining companies to invest in automated systems.

Middle East And Africa

- The African Mining Vision is driving investment in automation technologies to enhance the efficiency and sustainability of mining operations across the continent, with countries like South Africa leading the way.

- In the Middle East, the UAE is investing in smart mining initiatives, with companies like Emirates Global Aluminium exploring automation to improve operational efficiency and reduce costs.

Did You Know?

“Did you know that the use of autonomous trucks in mining can reduce operational costs by up to 15% while also improving safety by minimizing human error?” — International Council on Mining and Metals (ICMM)

Segmental Market Size

The Mining Automation Market is growing rapidly due to the increasing demand for operational efficiency and safety in mining operations. The key factors driving this market include the need for enhanced productivity, the adoption of advanced technology, and stringent regulations pertaining to the reduction of the environmental impact. Also, automation is increasingly being used by companies to reduce labor shortages and improve safety, which is crucial in hazardous mining environments. At present, the market is at the stage of implementation, with companies like Rio Tinto and BHP implementing the automation system in regions such as Australia. The main applications include drilling, loading, and monitoring, which help in the reduction of costs and the enhancement of operational efficiency. Also, the adoption of smart mining, the implementation of IoT, and the rising demand for digital transformation in the mining sector are boosting the growth of the market.

Future Outlook

The Mining Automation Market is expected to show substantial growth from 2024 to 2035, with a projected market value increase from $6.05 billion to $15.0 billion, a robust CAGR of 8.6%. The growth is due to the increasing use of advanced technology such as artificial intelligence, machine learning, and the Internet of Things (IoT), which have enhanced the operational efficiency and safety of mining operations. The automation market is expected to grow as a result of the drive for improved productivity and cost reductions. It is estimated that by 2035, more than 60% of mining operations will have some form of automation in place, up from approximately 30% in 2024. The market growth is also driven by increasing regulatory pressures to ensure worker safety and the environment. In addition, the increasing demand for minerals and metals is due to the transition to clean energy. The digital transformation of the mining industry has resulted in the development of new products and services, including self-driving vehicles, drones, and advanced data analytics tools. In addition, new trends such as remote monitoring and predictive maintenance are expected to gain traction and further enhance the role of automation in enhancing the efficiency and resilience of mining operations. As these trends continue to develop, the Mining Automation Market will continue to evolve into a key component of the industry’s future landscape.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Growth Rate | 7.20% (2022-2030) |

Mining Automation Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.