Market Share

Milk Tank Cooling System Market Share Analysis

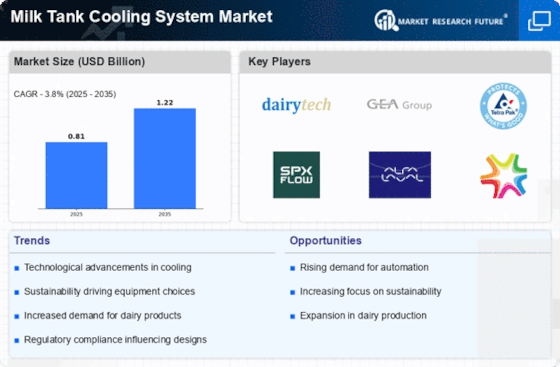

The milk tank cooling system market has witnessed notable trends in response to the evolving dairy industry landscape and the increasing emphasis on efficient milk storage and preservation. One prominent trend in this market is the growing adoption of advanced and energy-efficient cooling technologies. Dairy farmers are increasingly seeking milk tank cooling systems that not only ensure optimal milk temperature but also minimize energy consumption.

Besides, another significant trend is the integration of intelligent technology in milk tank cooling systems. In this modern age, the systems are fitted with sensors, automation and remote monitoring that allow farmers to keep a close watch on milk storage conditions and control them accordingly. This kind of cooling system delivers real-time temperature data; quality of milk and its performance allowing for proactive measures against spoilage and maintaining freshness of stored milk. The trend reflects more reliance in dairy industry on digital solutions to improve operational efficiency and preserve product quality.

Also, there has been a shift to modular and scalable cooling solutions within the market. Dairy farms differ in size or production capacity calling for expansion of modules without necessarily making major changes in infrastructure. This design flexibleness during installation accommodates diverse needs of dairy farmers by offering them options they can easily customize to suit their particular demands as well as budgetary constraints.

Moreover , hygiene and sanitation have become crucial considerations in the milk tank cooling system market sector. To respond to heightened concerns about food safety and quality standards, companies have included features that facilitate easy cleaning as well as maintenance of refrigerating machinery. Smooth surfaces, corrosion resistant tanks and cooling parts made from materials meeting strict hygiene guidelines are now used in order to maintain integrity of stored milk preventing it from being contaminated.

Thus energy recovery & sustainability are among key trends observed within Milk Tank Cooling Systems’ markets. These aspects contribute significantly towards overall energy consumption efficiency within dairy farms through some specific systems. Additionally, there is an emerging focus upon environmentally friendly refrigerants & sustainable manufacturing processes which help reduce environmental footprint related to cold chains. By doing so, our industry commits itself even further concerning response-ability environmentally speaking while matching global sustainabilities aspiration.

Furthermore, there has been growing demand for customized cooling solutions that are tailored to the specific needs of different regions and climates. For instance, dairy farming systems vary greatly depending on the climatic zones they are located in hence, cooling systems must be optimized for different environments. Manufacturers have developed regional-specific approaches taking into account factors such as ambient temperature, humidity and altitude among others to ensure optimum performance and efficiency in various agricultural settings.

In conclusion, there several dynamic trends shaping milk tank cooling system market. These dynamics reflect broader industry concerns surrounding sustainability, technology integration and hygiene standards. The adoption of energy-efficient, smart and modular cooling solutions is a testament of the industry’s resolve to optimize milk storage conditions while minimizing environmental impact. As dairy farming practices continue to evolve, stakeholders in the milk tank cooling system market are likely to witness further innovations and developments to meet the changing demands of the dairy industry.

Leave a Comment