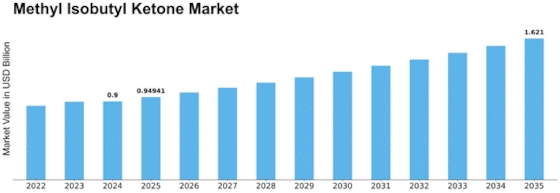

Methyl Isobutyl Ketone Size

Methyl Isobutyl Ketone Market Growth Projections and Opportunities

The Methyl Isobutyl Ketone (MIBK) market is influenced by various factors that shape its dynamics and performance. One of the primary drivers is the demand from end-use industries such as paints and coatings, adhesives, pharmaceuticals, and chemical manufacturing. The growth of these industries directly impacts the demand for MIBK, as it is widely used as a solvent and intermediate in the production of various chemicals and formulations. Additionally, the construction sector plays a significant role in driving the demand for paints and coatings, which, in turn, fuels the demand for MIBK.

The Methyl Isobutyl Ketone (MIBK) Market is also known as mono-isobutyl ketone. It is a stable, clear, and colorless liquid with a pleasant odor. Around 60% of the MIBK is manufactured by aldol condensation of acetone and its derivative intermediates, mesityl oxide, and diacetone alcohol.

Price trends in the petrochemical industry also affect the MIBK market. As MIBK is derived from acetone and isobutylene, fluctuations in the prices of these feedstocks can influence the overall cost of MIBK production. Furthermore, the availability and cost of energy sources such as crude oil and natural gas impact the production costs of MIBK manufacturers. Any disruptions in the supply chain or geopolitical tensions affecting the availability of raw materials can lead to fluctuations in MIBK prices.

Regulatory policies and environmental considerations play a crucial role in shaping the MIBK market. Stringent regulations regarding the use of volatile organic compounds (VOCs) in various applications, including paints and coatings, have prompted manufacturers to develop low-VOC formulations. MIBK, being a VOC, faces regulatory scrutiny, which drives the demand for alternative solvents and technologies. Moreover, environmental concerns regarding the disposal of chemical waste and emissions during production push companies to adopt sustainable practices, impacting the market dynamics of MIBK.

Global economic conditions and trade policies also influence the MIBK market. Economic growth in emerging markets drives industrial activities and construction projects, thereby increasing the demand for MIBK. On the other hand, trade tensions between major economies can disrupt the supply chain and affect the availability of MIBK in certain regions. Tariffs and trade barriers imposed on chemical imports can also impact the competitiveness of MIBK manufacturers in the global market.

Technological advancements and innovation play a pivotal role in the MIBK market. Continuous efforts to improve production processes, enhance product quality, and develop eco-friendly alternatives drive innovation in the industry. For instance, the development of bio-based solvents as substitutes for traditional petrochemical-derived solvents poses a challenge to the growth of the MIBK market. Companies investing in research and development to address environmental concerns and meet regulatory requirements gain a competitive edge in the market.

Market competition and industry consolidation are key factors influencing the MIBK market. The presence of established players with large production capacities and extensive distribution networks intensifies competition in the market. Merger and acquisition activities among key players lead to consolidation, reshaping the competitive landscape and impacting market dynamics. Additionally, the entry of new players and the emergence of regional manufacturers in developing economies contribute to market competition, driving innovation and price competitiveness.

Overall, the MIBK market is influenced by a complex interplay of factors ranging from industrial demand and raw material prices to regulatory policies and technological advancements. Adapting to these market dynamics requires strategic planning, innovation, and a deep understanding of evolving customer needs and preferences. Manufacturers and stakeholders in the MIBK industry must stay vigilant and responsive to these market factors to maintain competitiveness and sustain growth in the long term.

Leave a Comment