Lithographic Printing For Packaging Size

Lithographic Printing for Packaging Market Growth Projections and Opportunities

The Lithographic Printing for Packaging Market is influenced by a variety of market factors that collectively shape its dynamics and growth patterns. One of the primary drivers of this market is the demand for high-quality and visually appealing packaging. Lithographic printing, known for its exceptional print quality and color reproduction, caters to the growing consumer expectations for attractive and informative packaging. Brands across industries, including food and beverage, pharmaceuticals, and cosmetics, leverage lithographic printing to enhance their product packaging and create a strong visual impact on consumers.

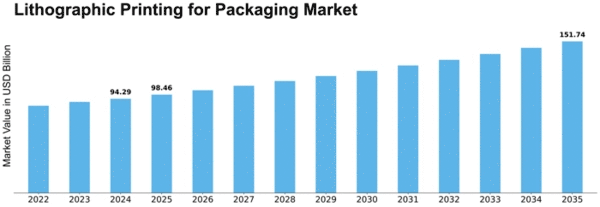

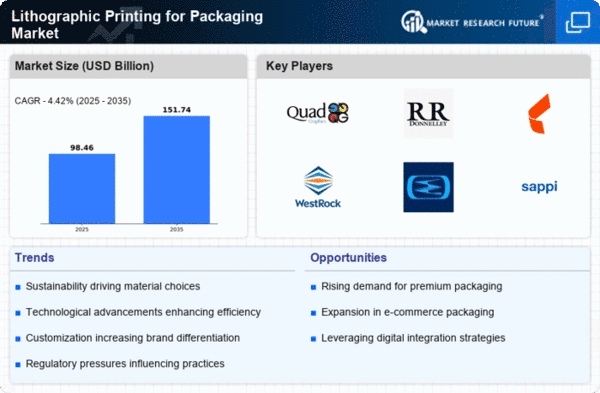

The global lithographic printing for packaging market is accounted to register a CAGR of 4.4% during the forecast period and is estimated to reach USD 134.0 Billion by 2032.

Technological advancements play a pivotal role in the Lithographic Printing for Packaging Market. Continuous innovation in lithographic printing presses, plate-making technologies, and ink formulations contribute to improved efficiency, cost-effectiveness, and environmental sustainability. Advancements in computer-to-plate (CTP) technology, for example, streamline the prepress process, reducing turnaround times and enhancing the overall productivity of lithographic printing for packaging.

The influence of sustainability is a crucial factor in the market dynamics of lithographic printing for packaging. As environmental concerns rise globally, there is a growing demand for eco-friendly packaging solutions. Lithographic printing can address this demand by offering sustainable practices, such as the use of water-based inks, recyclable substrates, and waste reduction measures. The adoption of green printing technologies aligns with the broader industry trend towards eco-conscious packaging solutions.

Market factors are also shaped by the regulatory landscape. Compliance with regulations related to food safety, product labeling, and packaging standards is critical for lithographic printing in the packaging industry. Regulatory bodies set guidelines to ensure that printed packaging materials meet safety standards and do not pose health risks to consumers. Adherence to these regulations is not only a legal requirement but also contributes to the overall reputation and credibility of lithographic printing providers.

Cost considerations are another significant factor influencing the Lithographic Printing for Packaging Market. While lithographic printing is renowned for its print quality, it is essential for manufacturers and brand owners to balance the benefits of superior printing with cost-effectiveness. The cost of materials, inks, and printing processes directly impacts the overall pricing of lithographically printed packaging. Striking the right balance between quality and cost is crucial to meet market demands and maintain competitiveness.

Consumer preferences and brand identity contribute to the market dynamics of lithographic printing for packaging. Brands often use packaging as a key element of their marketing strategy, and lithographic printing allows for intricate designs, vibrant colors, and detailed graphics. The ability to create visually appealing packaging that aligns with brand aesthetics and communicates product information effectively is a significant driver for the adoption of lithographic printing in the packaging industry.

The competitive landscape also shapes market factors in lithographic printing for packaging. With numerous printing technologies available, lithographic printing faces competition from digital printing, flexography, and other methods. Print service providers continually invest in modern lithographic presses and technologies to stay competitive, offering a range of printing solutions to meet diverse customer needs.

Leave a Comment