Top Industry Leaders in the Lithium Ion Battery Market

The Competitive Landscape of the Lithium-Ion Battery Market

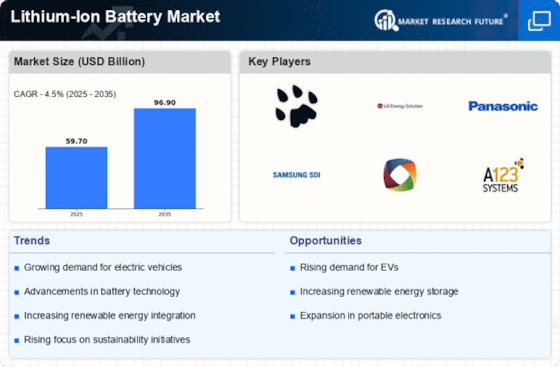

Lithium-ion batteries, once confined to portable electronics, have surged into the limelight as the lifeblood of the electric vehicle (EV) revolution and a cornerstone of a cleaner future. This dynamic market, pulsating with innovation and vying for dominance, demands a clear understanding of the competitive landscape, adopted strategies, key players, and emerging trends to ride the e-wave successfully.

Some of the Lithium-ion Battery companies listed below:

- Panasonic Sanyo

- Automotive Energy Supply Corporation (AESC)

- LG Chem.

- SAMSUNG SDI Co.

- Li-Tec Battery GmbH

- Toshiba

- A123 Systems

- GS Yuasa

- Sony Corporation

- Beijing Pride Power

Strategies Adopted by Leaders:

- Embracing Innovation and Advanced Technologies: Investing in R&D to integrate novel advancements like faster charging technologies, enhanced energy density materials, and artificial intelligence-powered predictive maintenance differentiates solutions and caters to future needs.

- Prioritizing Safety and Reliability: Guaranteeing stringent safety standards, rigorous testing protocols, and transparent risk management builds trust and mitigates customer concerns about battery fires or explosions.

- Partnerships and Ecosystem Building: Collaborating with automakers, energy providers, technology companies, and research institutions expands reach, offers comprehensive solutions, and strengthens brand presence.

- Focus on Vertical Integration and Supply Chain Security: Securing long-term supplies of critical raw materials like lithium and cobalt, establishing manufacturing facilities across strategic locations, and minimizing dependence on single suppliers ensures resilience and market stability.

- Sustainability and Environmental Considerations: Utilizing recycling technologies, minimizing carbon footprint in production processes, and offering second-life applications for retired batteries cater to customers with growing sustainability concerns.

Factors for Market Share Analysis:

- Product Portfolio and Technological Breadth: The range and sophistication of batteries offered, encompassing diverse chemistries like NMC, LFP, and solid-state batteries, with varying capacities, power outputs, and safety features, significantly impact market reach. Catering to specific applications, such as high-performance vehicles or extreme weather resilience, can be significant differentiators.

- Target Market Focus: Focusing on specific segments within the ecosystem, such as automotive manufacturers, energy storage systems, consumer electronics, or grid-scale applications, requires tailored solutions and partnership strategies. Addressing the unique needs of each segment can solidify market share within that niche.

- Manufacturing Scale and Efficiency: Optimizing production processes, minimizing material waste, and establishing large-scale battery factories are crucial for cost reduction and achieving economies of scale, a critical factor in a price-sensitive market.

- Sustainable Sourcing and Recycling: Utilizing ethically sourced raw materials, implementing closed-loop recycling programs, and minimizing environmental footprint ensure compliance with regulations and resonate with environmentally conscious customers.

- Software and Data Management: Providing robust battery management systems (BMS) for monitoring performance, optimizing charging, and ensuring safety enhances user experience and operational efficiency.

New and Emerging Companies:

- Niche-Focused Startups: Companies like QuantumScape and Solid Power specialize in developing next-generation solid-state batteries with increased safety, faster charging, and longer lifespans, cater to specific high-performance applications.

- Battery Management System (BMS) Specialists: Companies like Redwood Materials and ChargePoint focus on developing advanced BMS software and charging infrastructure solutions, adding value to existing battery technologies and enhancing user experience.

- Recycling and Sustainability Advocates: Companies like Li-Cycle and American Manganese develop innovative recycling technologies and closed-loop processes for recovering valuable materials from used batteries, addressing environmental concerns and resource scarcity.

Latest Company Updates:

Nov.13, 2023, Exxon Mobil (XOM.N), a pioneer in lithium-ion batteries, announced its plan to begin lithium production by 2026 in Arkansas. The initial production would roughly equal the amount needed to produce 100,000 EV batteries. Exxon has partnered with Tetra Technologies (TTI.N) and has also been testing unproven direct lithium extraction (DLE) technology that will be crucial for commercial operations.

Nov.09, 2023, A scientist team from Nanyang Technological University, Durapower Technology Singapore Pte Ltd., and Singapore (NTU Singapore) announced the development of a cloud-based technology that can enhance the lifespan and safety of lithium-ion batteries greatly. Powered by the IoT and AI, this new solution can help companies and data centers lower the risks associated with lithium-ion batteries, including potential fire hazards, particularly in hot and humid climates like Singapore.

Oct. 29, 2023, Researchers at the University of Tokyo announced the development of a prototype cobalt-free lithium-ion battery that can store around 60% more energy than alternatives of the same size. Prototype offers the potential to replace expensive, polluting material, Cobalt. Scientists worked on cobalt-free alternatives since the material is expensive and highly damaging to the environment.

Sep. 25, 2023, Shyam Metalics and Energy Limited (India), a producer and exporter of aluminum foil, announced its entry into lithium-ion battery-grade aluminum production. The company provides aluminum foil for various industrial applications with an annual production capacity of 20,000 tonnes per annum. Shyam Metalics' battery-grade aluminum foil will support the huge demand for critical components in lithium-ion cells from Indian companies foraying into the new-age batteries.