- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

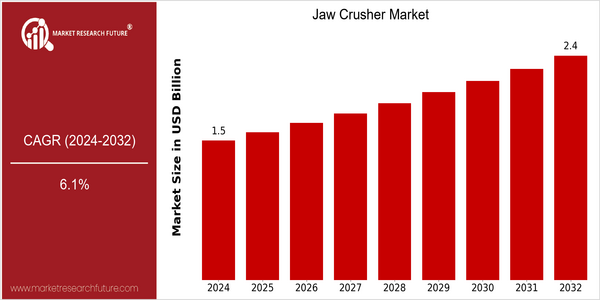

| Year | Value |

|---|---|

| 2024 | USD 1.5 Billion |

| 2032 | USD 2.4 Billion |

| CAGR (2024-2032) | 6.1 % |

Note – Market size depicts the revenue generated over the financial year

The global jaw crusher market is poised for significant growth, with a current market size of USD 1.5 billion in 2024, projected to expand to USD 2.4 billion by 2032, reflecting a compound annual growth rate (CAGR) of 6.1% over the forecast period. This upward trajectory indicates a robust demand for jaw crushers, driven by the increasing need for efficient material processing in various industries, including mining, construction, and recycling. As urbanization accelerates and infrastructure projects proliferate, the demand for high-performance crushing equipment is expected to rise, further propelling market growth. Several factors are contributing to this positive outlook, including advancements in technology that enhance the efficiency and durability of jaw crushers. Innovations such as automated controls, improved wear-resistant materials, and energy-efficient designs are attracting investments from key players in the market. Companies like Metso Outotec, Sandvik, and Terex Corporation are actively engaging in strategic initiatives, including partnerships and product launches, to strengthen their market position and meet the evolving needs of customers. For instance, recent product innovations aimed at reducing operational costs and increasing throughput are likely to capture significant market share, underscoring the competitive landscape of the jaw crusher market.

Regional Market Size

Regional Deep Dive

The Jaw Crusher Market is experiencing significant growth across various regions, driven by increasing demand for construction and mining activities. In North America, the market is characterized by advanced technology adoption and a strong focus on infrastructure development. Europe showcases a robust regulatory framework that emphasizes sustainability, while the Asia-Pacific region is witnessing rapid industrialization and urbanization, leading to heightened demand for jaw crushers. The Middle East and Africa are seeing investments in mining and construction, spurred by government initiatives. Latin America is gradually emerging as a key player, with a focus on resource extraction and infrastructure projects.

Europe

- In Europe, stringent environmental regulations are pushing manufacturers to develop eco-friendly jaw crushers, with companies like Sandvik and Kleemann leading the charge in sustainable technology.

- The European Union's Green Deal is influencing the market by promoting the use of recycled materials in construction, thereby increasing the demand for jaw crushers that can handle such materials.

Asia Pacific

- The Asia-Pacific region is experiencing rapid urbanization, particularly in countries like India and China, which is driving the demand for jaw crushers in construction and mining sectors.

- Government initiatives, such as China's Belt and Road Initiative, are leading to increased investments in infrastructure, further boosting the jaw crusher market in the region.

Latin America

- Latin America is gradually increasing its focus on mining and construction, with Brazil and Chile leading the way in resource extraction, which is positively impacting the jaw crusher market.

- The region is also witnessing a rise in foreign investments, with companies like Metso and FLSmidth establishing local partnerships to enhance their market presence.

North America

- The North American market is witnessing a surge in demand for jaw crushers due to the ongoing infrastructure projects, particularly in the United States, where the government has allocated significant funding for road and bridge repairs.

- Key players like Metso Outotec and Terex Corporation are innovating with advanced jaw crusher technologies that enhance efficiency and reduce operational costs, which is expected to drive market growth.

Middle East And Africa

- In the Middle East, countries like Saudi Arabia are investing heavily in mining and construction projects, which is expected to significantly increase the demand for jaw crushers.

- The African market is seeing a rise in mining activities, with companies like Epiroc and Atlas Copco expanding their operations, thereby enhancing the availability of jaw crushers in the region.

Did You Know?

“Did you know that jaw crushers are one of the oldest types of crushers, dating back to the 19th century, and they are still widely used today due to their reliability and efficiency?” — Mining and Construction Technology Journal

Segmental Market Size

The Jaw Crusher Market segment is currently experiencing stable growth, driven by the increasing demand for construction and mining activities. Key factors propelling this segment include the rising need for efficient material processing in various industries and the push for sustainable mining practices that require advanced crushing technologies. Regulatory policies aimed at reducing environmental impact also play a significant role in shaping demand, as companies seek to comply with stricter guidelines while maintaining productivity. Currently, the adoption stage of jaw crushers is at a mature level, with notable players like Metso, Sandvik, and Terex leading the market. These companies have established a strong presence in regions such as North America and Asia-Pacific, where infrastructure development is robust. Primary applications of jaw crushers include aggregate production, mining operations, and recycling processes, with industries like construction and metallurgy heavily relying on these machines. Trends such as the shift towards automation and the integration of IoT technologies are catalyzing growth, as companies seek to enhance operational efficiency and reduce downtime.

Future Outlook

The Jaw Crusher Market is poised for significant growth from 2024 to 2032, with a projected market value increase from $1.5 billion to $2.4 billion, reflecting a robust compound annual growth rate (CAGR) of 6.1%. This growth trajectory is underpinned by the rising demand for construction and mining activities, particularly in emerging economies where infrastructure development is a priority. As urbanization accelerates, the need for efficient material processing solutions will drive the adoption of jaw crushers, enhancing their penetration in various sectors including construction, mining, and recycling. Key technological advancements, such as the integration of automation and IoT capabilities in jaw crushers, are expected to further propel market growth. These innovations not only improve operational efficiency but also enhance safety and reduce downtime, making jaw crushers more appealing to end-users. Additionally, stringent environmental regulations are pushing manufacturers to develop eco-friendly and energy-efficient models, aligning with global sustainability goals. As a result, the market is likely to witness a shift towards more advanced and sustainable crushing solutions, positioning jaw crushers as essential equipment in the evolving landscape of material processing.

Jaw Crusher Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.