Italy Ceramic Additive Manufacturing Market Summary

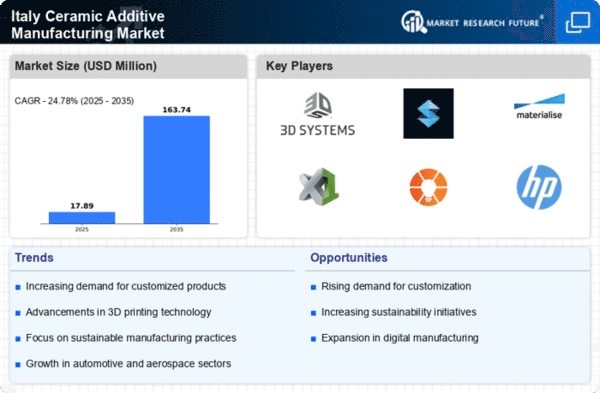

As per Market Research Future analysis, the Italy Ceramic Additive Manufacturing Market Size was estimated at 14.34 USD Million in 2024. The Italy ceramic additive-manufacturing market is projected to grow from 17.89 USD Million in 2025 to 163.74 USD Million by 2035, exhibiting a compound annual growth rate (CAGR) of 24.7% during the forecast period 2025 - 2035

Key Market Trends & Highlights

The Italy ceramic additive-manufacturing market is poised for growth driven by technological advancements and sustainability initiatives.

- Technological advancements are enhancing the efficiency and precision of ceramic additive manufacturing processes.

- Sustainability initiatives are increasingly influencing production methods, aligning with global environmental goals.

- The largest segment in this market is the construction sector, while the fastest-growing segment is likely the aerospace industry.

- Rising demand for customization and the integration of Industry 4.0 technologies are key drivers propelling market expansion.

Market Size & Forecast

| 2024 Market Size | 14.34 (USD Million) |

| 2035 Market Size | 163.74 (USD Million) |

| CAGR (2025 - 2035) | 24.78% |

Major Players

3D Systems (US), Stratasys (US), Materialise (BE), ExOne (US), EOS (DE), HP Inc. (US), GE Additive (US), Sculpteo (FR), CeramTec (DE)