Market Trends

Key Emerging Trends in the Inspection Analysis Device Market

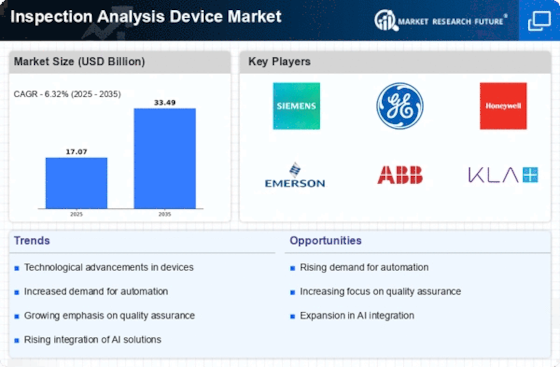

The inspection analysis device market is witnessing several notable trends that are shaping its trajectory and influencing the way businesses approach quality control, safety compliance, and efficiency enhancement. One prominent trend is the increasing adoption of automation and artificial intelligence (AI) technologies. As businesses strive to streamline their operations and improve productivity, they are turning to automated inspection analysis devices that can perform tasks with greater speed, accuracy, and consistency than traditional manual methods. AI-powered devices can analyze large volumes of data quickly and identify patterns or anomalies that may indicate defects or compliance issues, enabling proactive problem-solving and decision-making.

Another significant trend in the inspection analysis device market is the growing emphasis on sustainability and environmental responsibility. With increasing awareness of the environmental impact of industrial processes, businesses are seeking inspection devices that not only ensure product quality and safety but also minimize waste, energy consumption, and environmental pollution. As a result, there is a rising demand for eco-friendly inspection technologies that are energy-efficient, recyclable, and minimize the use of harmful chemicals or materials in the inspection process.

Furthermore, there is a notable trend towards the integration of advanced sensor technologies in inspection analysis devices. Sensors such as spectrometers, thermal imaging cameras, and ultrasonic detectors enable devices to capture and analyze a wide range of data, including temperature, chemical composition, and structural integrity. By leveraging multiple sensor technologies, inspection devices can provide comprehensive insights into the quality and condition of products, materials, or equipment, facilitating more informed decision-making and risk mitigation strategies.

Additionally, there is a growing trend towards the development of portable and handheld inspection analysis devices. These compact and lightweight devices offer flexibility and convenience, allowing inspectors to perform on-site inspections quickly and efficiently, without the need for bulky equipment or specialized facilities. Portable inspection devices are particularly valuable in industries such as construction, automotive, and oil & gas, where inspections may need to be conducted in remote or hazardous environments.

Moreover, there is an increasing demand for cloud-based inspection analysis solutions that offer real-time data monitoring, analysis, and reporting capabilities. Cloud-based platforms enable seamless collaboration and information sharing among stakeholders, regardless of their location, facilitating faster decision-making and response times. Furthermore, cloud-based solutions offer scalability and flexibility, allowing businesses to adapt to changing inspection requirements and scale their operations as needed.

Furthermore, the inspection analysis device market is witnessing a trend towards customization and modularization. Businesses are increasingly seeking inspection solutions that can be tailored to their specific needs and requirements, rather than relying on one-size-fits-all solutions. Modular inspection systems allow businesses to select and integrate components based on their unique workflows, processes, and objectives, enabling greater flexibility and efficiency in inspection operations.

Leave a Comment