Market Trends

Key Emerging Trends in the Inorganic Rheology Modifiers Market

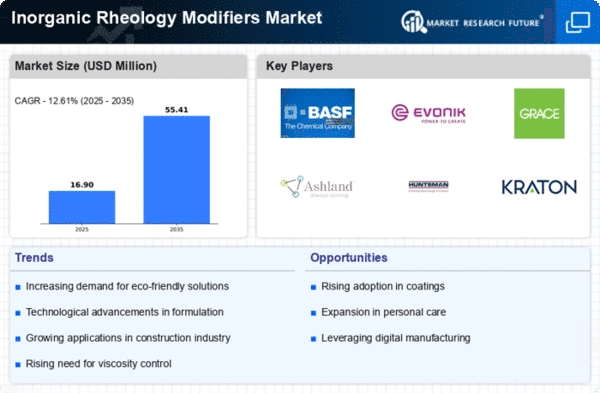

The market trends of the inorganic rheology modifiers industry have witnessed significant evolution in recent years, reflecting the dynamic nature of the global market. Inorganic rheology modifiers play a crucial role in enhancing the viscosity and flow properties of various materials across different industries, including paints and coatings, adhesives, and construction. One prominent trend shaping this market is the growing demand for environmentally friendly and sustainable solutions. As the world increasingly focuses on sustainable practices, manufacturers are exploring inorganic rheology modifiers that are eco-friendly and comply with stringent environmental regulations.

Another noteworthy trend is the surge in research and development activities within the industry. With continuous technological advancements, companies are investing in developing innovative inorganic rheology modifiers that offer improved performance and cater to specific applications. This trend not only fosters competition but also provides end-users with a diverse range of options to meet their unique requirements. The focus on customization is evident as manufacturers strive to formulate inorganic rheology modifiers that address the specific needs of different sectors, such as pharmaceuticals, textiles, and personal care products.

Globalization and increasing cross-border trade are influencing the market trends as well. Manufacturers are expanding their reach and collaborating with international partners to tap into new markets and gain a competitive edge. This has led to the standardization of quality and regulatory compliance, ensuring that inorganic rheology modifiers meet the stringent requirements of diverse regions. Additionally, the rise in infrastructure development projects, particularly in emerging economies, is boosting the demand for inorganic rheology modifiers in the construction industry.

Cost-effectiveness is a key factor driving market trends in the inorganic rheology modifiers sector. As industries seek to optimize production costs, manufacturers are focusing on the development of cost-effective solutions without compromising on performance. This has led to the introduction of value-based products, making inorganic rheology modifiers more accessible to a wider range of end-users. The market is witnessing a shift towards economies of scale, with bulk production helping manufacturers achieve cost efficiencies.

Furthermore, advancements in nanotechnology are influencing the market dynamics of inorganic rheology modifiers. Nanoparticles are being incorporated into these modifiers to enhance their performance characteristics, such as stability and dispersion. This innovative approach is gaining traction, especially in applications where precise control over rheological properties is critical. As nanotechnology continues to evolve, it is likely to open up new avenues for the inorganic rheology modifiers market.

Challenges also shape the market trends of inorganic rheology modifiers. The industry faces hurdles related to the toxicity of certain inorganic materials and their impact on human health and the environment. As a response, there is a growing emphasis on developing safer alternatives and sustainable manufacturing practices. Regulatory bodies are actively addressing these concerns, leading to the introduction of guidelines and standards to ensure the responsible use of inorganic rheology modifiers.

Leave a Comment