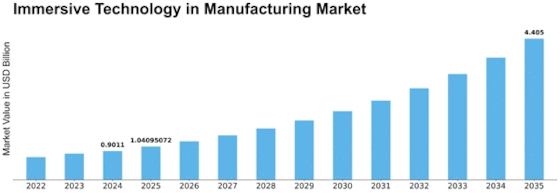

Immersive Technology In Manufacturing Size

Immersive Technology in Manufacturing Market Growth Projections and Opportunities

Immersive technology has transformed industrial processes and improved operational efficiency. Immersive technologies like VR and AR are being incorporated into industrial procedures to solve problems. Immersive technology is used in manufacturing to increase training and skill development. VR's realistic simulations allow workers to train in virtual settings, shortening the learning curve and improving operators' skills with complicated apparatus and procedures.

Design and prototyping are similarly affected by immersive technology in production. Creating virtual prototypes with VR makes engineering and design more natural and collaborative. This speeds up product development and minimizes the need for physical prototypes, saving money and improving market agility. AR provides assembly line workers with step-by-step guidance and vital information in real time, reducing mistakes and improving production accuracy.

Immersive technology also optimizes factory maintenance and repair. AR apps let technicians view equipment specs, maintenance procedures, and troubleshooting manuals in real time, minimizing downtime and enhancing machinery dependability. Proactive maintenance prevents unplanned outages and ensures manufacturing process continuity.

Remote cooperation using immersive technology affects the industrial market's dynamic character. AR-powered smart glasses and virtual collaboration platforms allow specialists and engineers to guide and help on-site staff in real time. In a multinational industrial environment, where firms generally have several locations, this skill helps with problem-solving, information sharing, and decision-making.

The immersive technology manufacturing sector faces early investment expenses and integration issues. Due to the upfront costs of hardware, software, and training, some manufacturers may hesitant to implement immersive technology despite its long-term benefits. Planning and coordination are needed to ensure smooth integration with current systems and processes without disrupting production operations.

Leave a Comment