Hybrid Fabric Size

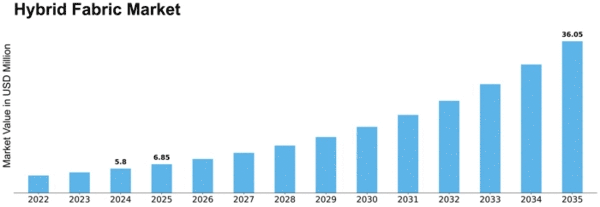

Hybrid Fabric Market Growth Projections and Opportunities

The hybrid fabric market is influenced by a variety of factors that collectively shape its dynamics and growth trajectory. One key factor is technological advancements. As technology evolves, new materials and manufacturing processes emerge, leading to the development of innovative hybrid fabrics with enhanced properties such as durability, flexibility, and sustainability. These advancements drive market growth by catering to diverse consumer needs and preferences, spurring demand across various industries including automotive, aerospace, sports and leisure, and fashion.

The Hybrid Fabric refers to the type of fabrics which consist more than one type of structural fiber. These types of fabrics are the specialty fibers that has wide range of applications in the major end-use industries such as automotive, aerospace & defense and energy. In this multi-layered laminate, the required property of each fiber can be provided with addition of the desired fabric.

Another significant market factor is consumer awareness and preferences. With growing environmental consciousness and concerns about sustainability, there is an increasing demand for eco-friendly hybrid fabrics made from renewable sources or recycled materials. Consumers are also becoming more discerning about product quality and performance, favoring hybrid fabrics that offer superior comfort, breathability, and moisture-wicking properties. As a result, manufacturers are compelled to invest in research and development to meet these evolving consumer expectations, thereby shaping market trends and driving competition.

Market regulations and policies also play a crucial role in influencing the hybrid fabric market. Government initiatives aimed at promoting sustainable manufacturing practices and reducing carbon emissions have led to the implementation of stringent regulations governing the production and use of certain chemicals and materials in textile manufacturing. Compliance with these regulations not only ensures environmental sustainability but also fosters consumer trust and confidence in hybrid fabric products. Moreover, trade policies and tariffs can impact market dynamics by affecting the cost of raw materials and finished goods, thereby influencing pricing strategies and market competitiveness.

Global economic factors such as GDP growth, inflation rates, and exchange rates also have a significant impact on the hybrid fabric market. Economic downturns can lead to reduced consumer spending and demand for discretionary items like apparel and luxury goods, thereby affecting the sales of hybrid fabric products. On the other hand, rapid industrialization and urbanization in emerging economies can create new growth opportunities for market players by expanding their consumer base and opening up new markets. Additionally, currency fluctuations can impact the cost of imported raw materials and affect the profitability of manufacturers operating in global markets.

Supply chain dynamics and raw material availability are also critical market factors that influence the hybrid fabric market. Fluctuations in the prices of raw materials such as cotton, polyester, nylon, and spandex can impact production costs and profit margins for manufacturers. Supply chain disruptions, whether due to natural disasters, geopolitical tensions, or pandemics, can also disrupt manufacturing operations and lead to shortages in raw materials, thereby affecting product availability and pricing. As a result, manufacturers often engage in strategic sourcing and diversification of suppliers to mitigate risks and ensure a stable supply of raw materials.

Leave a Comment